Researchers from the Universitat Politècnica de Catalunya in Spain evaluated 12 PV devices of 11 suppliers for use indoors, where different systems can be identified to feed external sensor nodes with a surface of 10 cm² and continue testing under natural interior light.

Researchers from the Universitat Politecnica de Catalunya in Spain evaluated a dozen indoor PV modules of eleven suppliers with the aim of identifying a PV-based diet for external sensor junctions with 10 cm2 available surface.

The modules, some of which were prototypes, were based on perovskiet, monocrystalline and polycrystalline silicon, amorphous silicon, organic PV (OOG) and III-V technologies.

“The effort was motivated by two projects that require autonomous sensors” that would use free optical energy that comes from natural daylight and artificial lighting available indoors, “said the corresponding author of the research, Ferran Reverter, said PV -Magazine.

The group opted for an indoor PV-driven device for this type of application because of its wireless nature and potential for a long service life, whereby the limitations of primary batteries are changed that must be changed or designed with a grid connected to the cabling.

They also noted that being able to do an “honest and direct comparison” of the products of indoor module module suppliers “unfeasible” using the corresponding data sheets because the test conditions have been defined by each manufacturer.

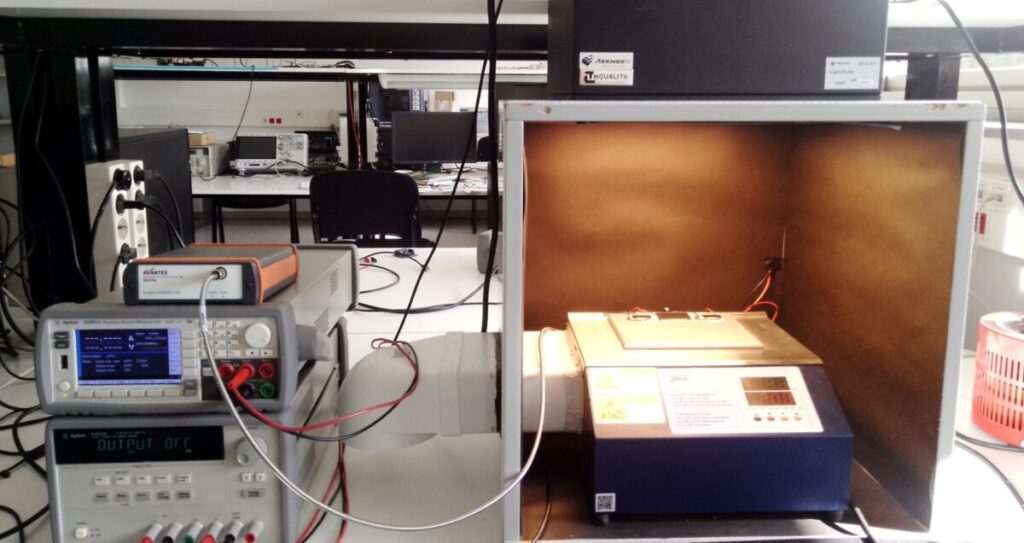

An adapted automatic test system has been developed to characterize the PV modules below artificial lighting in the range of 100 LX to 1000 LX. The reference conditions were 1000 LX and 25 C Business and Maximum Working Point (MPP). Testing was conducted under four different indoor artificial lighting types for a total of 48 different module/light pairs.

The compact fluorescent (CFL) and halogen-type light bulbs (hall) was supplied by commercial lamps that were driven by a variable transformer, while the cold LED (C-LED) and warm LED (W-led) were dependent on a spectral adjustable light source, Asens set deck light Cube.

The modules came from Anysolar, AMX Solar, Panasonic, Powerfilm, Dracula Technologies and various other manufacturers, including three perovskite solar modules, chosen “because this is the new, cheap technology that is suggested for future indoor applications,” said the researchers.

The module/light pairs were evaluated on power density, efficiency, filling factor and linearity to find the optimum couples for indoor applications.

“The best figures are supplied by PV modules that belong to the III-V group. Given the high costs of this technology, the most attractive PV technologies for indoor applications seem to be the organic and perovskiet,” said Reverter. “Although the power on the output of the PV cells in indoor applications is much lower than outdoors, the results are promising to feed autonomous sensors.”

Based on their experimental results, the team did indeed say that the monocrystalline and polycrystalline silicon modules were most suitable for HAL -light, with an efficiency of “up to 20% at 1000 LX.” For the C-conducted, W-guided and CFL lights, the most suitable module was the one belonging to the III-V group, with an efficiency of up to 39% at 1000 LX.

“But given the high costs of such a technology, however, are an alternative solution for C-LED, W-LED and CFL and the organic and perovskiet modules, the efficiency of which can be up to 14% and 22%, at 1000 LX,” said the scientists who add that acceptance is able to access commercially available PV modules.

The research is described in detail in “PV cells with low area under artificial lighting indoors: a comparative study“Published in Ieee transactions on instrumentation and measurement.

The group is now conducting a similar study, but under natural daylight conditions instead of artificial lighting. “Then the next step is the design of Low-Power Power Management circuits that are in charge of following the maximum working point (MPPT) of the PV modules,” said Reverter.

This content is protected by copyright and may not be reused. If you want to work with us and reuse part of our content, please contact: editors@pv-magazine.com.