Scientists in India have built a prototype for thermal solar geysers on solar energy based on a nichrome wire heating bar and a flexible pipe heat exchanger with aluminum fins. The system is designed to generate domestic how water and is said to reach a level of energy costs of $ 0.051 per kWh.

A group of researchers from the Indian National Institute of Technology and the National Institute of Solar Energy have developed a PV-driven thermal solar geiser (TSG) that makes it possible to convert the day of thermal oil by converting PV electricity into heat via a nichrome wire heater.

“Our TSF offers consistent performance and reliable hot water, even during periods of low sunlight Because of the thermal storage capacity and solar energy photovoltaic integration, ‘the main author of the research, Dineh Kumar Sainitold PV -Magazine. “It also offers a long operational life, while it needs less maintenance and Making effective heat retention and reliable hot water delivery possible during low solar radiation and night hours.“

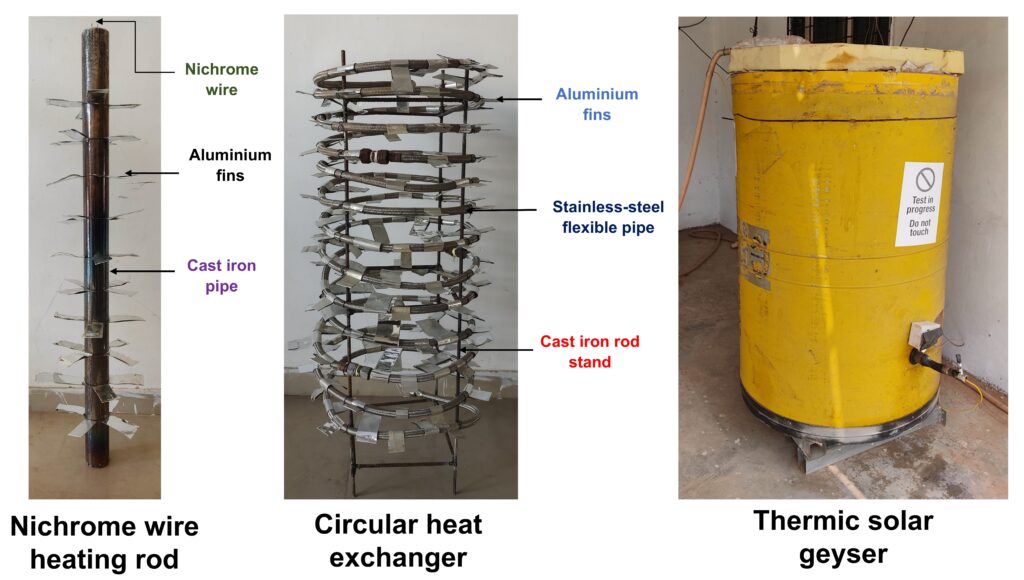

The TSG system has a nichrome wire heating rod designed with aluminum fins attached to the radial heat transfer and a circular heat exchanger made from flexible stainless steel pipes and aluminum fins. It uses 450 l of a thermal oil that is known as a therminol VP as a storage medium, because of the stability and efficiency at high temperature in thermal applications for solar energy.

In the proposed system configuration, the circular heat exchanger facilitates efficient heat transfer from the thermal oil to the incoming cold water, so that hot water at the exhaust. The cylindrical heating rod includes a ceramic strip, nichrome wire, aluminum fins and fine sand. The nichrome thread consists of a resistance heating element made from a nickel chromium alloy.

The experimental setup included six 300 W poly crystalline solar panels supplied by the Indian manufacturer PV Power Tech, a heating bar, a fin, a pipe heat exchanger, the TSG, a pyranometer, thermocouples, a data log and a power analyzer.

“The wire is wrapped around the ceramic strip in a spiral configuration and placed centrally in the rod,” the scientists explained. “Fine sand fills the rod and effectively prevents direct contact between the nichrome wire and thermal oil, which eliminates the risk of oil vapor. The nichrome wire puts electrical energy from the PV panels to the thermal energy, which is stored and transmitted by the fine sand to the therminol Vpest.”

Image: National Institute of Technology

The scientists evaluated the performance for 240 l of daily hot water demand for two consecutive days with a constant current speed of 1 liter per minute (LPM), under three realistic domestic user scenarios: 80l (three times daily), 120l (twice a day) and 240L (once a day).

The analysis showed that the loading behavior of the system can vary considerably, depending on the intensity of the solar radiation, whereby the input of thermal energy increases with high radiation levels. With low radiation, on the other hand, the generation of heat is slower and it is longer at loading time. It also showed that, for a four-day loading operation, the average thermal oil temperature rose from 32.67 ° C to 101.83 ° C, with the average loading efficiency of the PV panels, TSG and the total system are 12.32%respectively, 89.69%and 11.05%.

“During a 12 -hour discharge operation, the thermal oil temperature decreased from 103.63 ° C to 48.39 ° C at 1 LPM, successfully 720 l water with an average temperature rise of 16.4 ° C between the inlet and exhaust valve,” explained Kumar Saini that the system was also able Heat 240 l water daily for two consecutive days, which guarantees reliable hot water delivery for household applications. “It also showed an effective overnight heat resistance under various operational conditions, with registered heat limitation efficiency of 94.15 %, 93.84 %and 86.68 %for discharging 80 l, 120 l and 240 l of hot water respectively.”

Further techno-economic analysis showed that the system is said to be viable with an initial capital costs of $ 1373.39, an expected lifetime of 25 years and a calculated livalized energy costs (LCOE) of $ 0.051 per kWh. “The estimated payback time is 5.24 years, so that the cost -effectiveness for domestic hot water applications is confirmed,” said Kumar Saini. “During its lifespan, the TSG system reaches a total collaboration of 104 tons and a net mitigation of 77.92 tons, emphasizing the benefits of the environment and the contribution to reducing carbon emissions.”

The system was described in the study “Development and performance evaluation of a photovoltaic integrated thermal solar giver for household water heating“Published in Thermal science and technical progress.

This content is protected by copyright and may not be reused. If you want to work with us and reuse part of our content, please contact: editors@pv-magazine.com.

Popular content