Insight into the costs related to the production of green hydrogen from renewable sources is essential to evaluate its large -scale viability in a global energy context. From this perspective, Enertis Applus+ carried out a comparative analysis of the production costs of green hydrogen production to analyze the level of hydrogen (LCOH) at ten international locations with different levels of solar and wind sources, using off-grid electrolyzers that are exclusively driven by renewable electricity systems.

Thanks to a rigorous approach, with more than 4,000 simulations and a detailed analysis of each scenario, the study offers a solid route map to understand where, how and under the circumstances green hydrogen can be produced at competitive costs.

The study analyzed a wide range of hybrid configurations of photovoltaic solar plants, wind farms and battery energy storage systems (BESS) to identify the most efficient and economically competing combinations. The analysis model kept the electrolyzer power constant and only varied the composition of the generation sources and energy storage capacity of the system. This approach made comparable scenarios possible at all locations.

A precise evaluation of system performance in various production, energy costs and price scenarios

The system architecture is based on an off-grid electrolysis station that is exclusively powered by a tanning factory, a wind farm and a BESS system, all new installed. With 100 MW electrolysis capacity, any excess energy that is not used by the Electrolyzer is stored in the battery system, if the loading condition allows it. This design reduces limitation, makes it possible to use renewable production more efficiently and offers the possibility to study the strategic role of storage in energy management and its impact on costs.

Figure 1 shows the general schedule at which the various iterations were performed:

Figure 1: System architecture. Source: Own effect

Based on the variability in wind and sun sources, suitable locations were identified in Spain (five locations), Romania, Chile (two locations), Australia and the United States. The analysis method determined a common basic case that made accurate evaluation of system performance possible under different combinations of renewable technologies. The basic structure of the base included 100 MW electrolysis, 100 MWAC photovoltaic solar energy, 99 MW wind and no storage capacity. From this principle, 240 iterations were carried out per location, where various renewable forces and storage capacities were combined, while the electrolyzing capacity was kept constant.

The analysis of gross and net available energy was an important part of the research. Initially, hourly simulations were obtained to determine the gross energy amount and the total potential energy production without limitations. Subsequently, limitations, losses, losses and actual performance were calculated for each scenario using internal developed simulation systems. Based on the net available energy and the operating conditions of the electrolyzers, the annual hydrogen production was determined for every analyzed configuration.

The economic calculations were organized on the basis of two scenarios and the estimate of investment costs (Capex) and operating costs (OPEX). On the one hand, a model with standard prices, independent of the location, was defined. In this scenario the same cost values were used to calculate the level of energy costs (LCOE) and LCOH at all locations, therefore the variability of the results was directly related to the availability of renewable energy sources. On the other hand, a second scenario was defined in which variable prices – adapted according to economic estimates and the financial situation of each country – were introduced. A total of 4,800 simulations were carried out: 2,400 with standard prices and an equal number with variable prices.

The identification of scenarios for the optimization of electricity and hydrogen production costs was one of the most important aspects of the analysis. Two reference frameworks were defined for this: a basic scenario that made a homogeneous comparison between locations possible; And an optimal scenario, in which the LCOH was minimized at every location through system architecture. This approach emphasized that the configuration that the most hydrogen produced was not always the one who reached the lowest LCOH. In that sense, the balance between energy covering and the capacity factor of the Electrolyzer turned out to be decisive. At locations with a low LCOE it was more viable to exaggerate the renewable generation, even if a certain level of limitation was involved, to guarantee a higher capacity factor of the electrolysis system. At locations with a higher LCOE, on the other hand, the economic fine for restrictions forced greater efficiency in the proportion of renewable capacity/electrolysis capacity.

Resource, capacity factor for electrolyzer and financial circumstances: determine factors

One of the most important findings of the study is that the availability of renewable sources on each site directly determines the hydrogen production potential. In this respect, locations that benefit from a complementary mix of renewable sources – such as photovoltaic solar and wind – have considerable advantages. This complementarity makes higher capacity factors for the electrolyzer possible, resulting in a lower LCOH and a greater general system efficiency.

The study shows that the configurations where the operation of the electrolyzer is maximized-well-managed renewable generation presented considerably lower LCOH. This was, for example, the case of locations such as Texas (US) or Cádiz (Spain), where the complementarity between solar and wind sources was possible for achieving factors with high capacity and a significant reduction in LCOH, less than $ 3.6/kg in the standard scenario. The same configuration, on the other hand, has been implemented in regions such as Romania, where Capacity Factors from Electrolyzer are considerably lower, reaches LCOH values of up to $ 5.5/kg.

Conversely, sites with a limited availability of one energy sources showed considerably lower electrolyzing capacity factors, which translated into higher LCOH values. For example, locations such as North -Chili, with low wind availability, showed very reduced electrolyzing capacity factors, which translated into LCOH values above $ 5/kg. In the standard architecture, even in these cases optimized configurations could be identified. By eliminating the wind component and strengthening solar generation, the LCOH was reduced to $ 4.1/kg, which shows that system optimization not only depends on the gross availability of renewable sources, but also – criticism – on the design strategy and the generation architecture used.

The study also emphasizes the decisive impact of local economic conditions. Factors such as Capex, OPEX and project evaluation percentages can significantly influence the final costs, so it is essential to consider them in the planning and economic analysis of projects. Locations with good resources can therefore lose competitiveness in scenarios with variable prices as a result of unfavorable investment costs or inflation rates. That is why the high availability of resources, although a necessary condition, is not sufficient to guarantee a competitive LCOH. For example, locations such as Texas can experience an increase in their LCOH of more than $ 1/kg because of the higher Capex related to the transition from the standard price scenario to a location-corrected price scenario. These variations can also be observed when changing the return rates of the financial model, with differences of more than $ 1.5/kg in some locations.

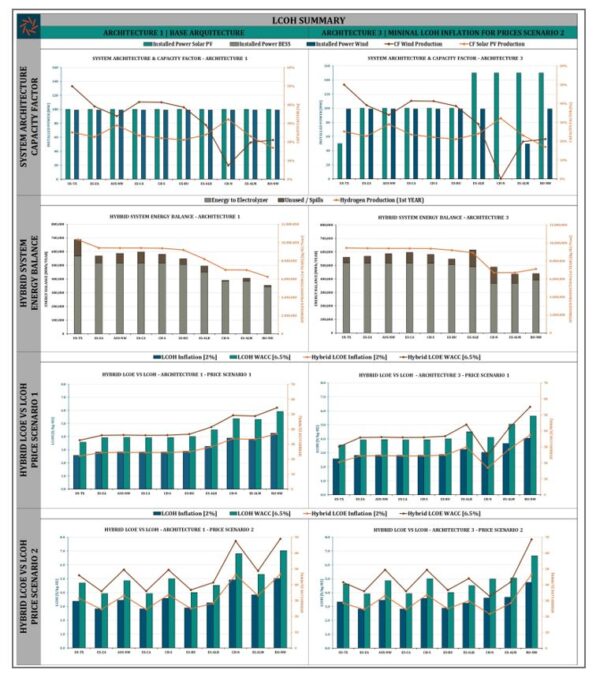

The following table provides an overview of the behavior of the aforementioned variables in the various architecture and price scenarios:

Table 1: Summary of LCOE & LCOH. Source: Own effect.

Moreover, the following figure can be observed in the behavior of the specified LCOH in the various concepts that include them, and the evolution of each of them can be observed.

Table 2. Specified LCOH. Source: Own effect.

As a conclusion, the level of hydrogen depends on a complex interaction between technical, operational and economic variables. A high capacity factor of the electrolyzer, a reduced LCOe and favorable financial circumstances are the three pillars on which every strategy for green hydrogen production must be based. None of these factors is taken sufficiently independently, but their effective combination and adjustment to each location determines the difference between a viable project and an economically unfeasible.

Enertis Applus+ is a Spain based on full-range Engineering consultancy with extensive expertise in the renewable energy and storage sectors. As pioneers in tests and quality control and specialists in technical advisory services, it offers an integrated insight into PV, wind and bES projects for solar energy on technical, environmental, financial and contractual project phases.

The views and opinions expressed in this article are the author, and do not necessarily reflect it by PV -Magazine.

This content is protected by copyright and may not be reused. If you want to work with us and reuse part of our content, please contact: editors@pv-magazine.com.

Popular content