Researchers from the German Institute try to reduce silver use in PV devices in hetero junction under the umbrella of extensive research projects. Under their recent performance there is the manufacture of a heterojunction cell that a minimal silver consumption of only 1.4 mg per W.

Researchers from the Fraunhofer Institute for Solar Energy Systems (Fraunhofer Isee) of Germany are currently working together with various industrial partners on innovative solutions to drastically reduce silver consumption for the heterojunction (HJT) solar cells under the umbrella of the Hit research project financed.

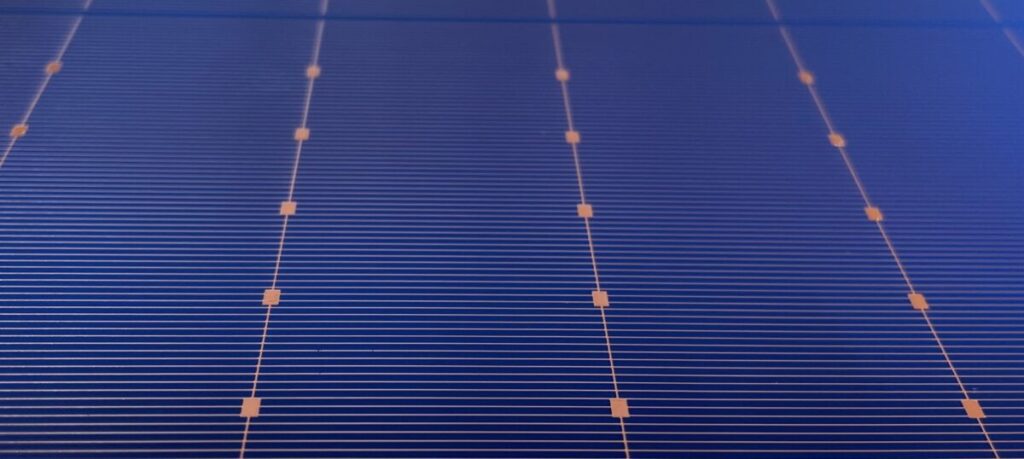

“Within this work, Fraunhofer ISE has investigated various metallization units using screen-printed silver buyer and copper pasta on HJT sun cells,” told the management of the research project, Andreas Lorenz, to PV -Magazine. “Our goal is to greatly reduce silver consumption on the one hand, but to obtain a high conversion efficiency on the other hand by ensuring very good optical and electrical performance of the screen printing metallization patterns.”

According to Lorenz, achieving the proposed goal can be possible if very fine lines can be realized, in particular on the front cell side with the help of pasta with reduced silver content, where silver is strongly reduced on the back, or even completely avoided, by using pure copper pasta.

“To realize such fine lines in screen prints, new screen configurations with ultra-final meshes can be beneficial to realize ultragin and uniform contacts,” he added. “We have developed a model to calculate, compare and optimize effective silver use for different screen configurations. It is shown that a factor of 2 can be increased when using metallization pastas made of silver and copper with new mesh configurations instead of pure silver pastas.”

With the help of the Fraunhofer ISE’s Gridmaster simulation tool, the researchers have performed a series of simulations with different metallization variants to realize very efficient solar cells with minimal silver consumption. The experiment showed that conventional metallization with silver paste on the front and back can gradually be replaced by AGCU and PURE CU pastas, and that an ultrafine line metallization with openings up to 13 μm can be printed using new ultra-fine mesh-scenes established in Japan Mesh-Leven-Leven-Liedh-Estate-Liedh-Liedhethetleh-Liedh-Liedhethet Hetleh Estate Sheet Shed Sheet Shed Let Shed Sheet Shed Sheet Shed Located Located, Weven Located In Shed Located, Weven Lied Sheet Shed Located Mesh Fair Shed, Weven Lied Sheet, Weven Mesh Fair Shed In Japan Lied In Japan Lied A Asad, Mesh Fair Sheds Estate Located in Japan. Ltd.

“An optimal combination of AGCU paste on the front and pure CU pasta on the back, combined with an optimized fine printing process, made it possible to produce highly efficient HJT sun cells with a minimum silver consumption of only 1.4 mg of silver per W,” Lorenz explained. “This means that even the long -term goal of a silver consumption of less than 2 mg per W has been successfully demonstrated for the first time.”

The solar cells were also found to achieve even higher efficiency than the silver -aged reference cells with minimal silver consumption. ‘The Relative Increase in Efficiency on the Silver Saving Cells With Agcu and CU Metallization is 0.9%, ”Fraunhofer Isee Researcher, Sebastian Pingel, Said.“ We Achieuwed this result when we printed finer lines on the front of 17 µm inade of 20 µm inad of 20 µm inad of 20 µm inad of 20 µm inad of 20 µm inad or 20 µm inade or 20 µm. AG and CU Instead of AG On The Rear Side. ”

“Unfortunately we did not calculate this for the specific cells,” said Lorenza, when he was asked about possible improvements in production costs. “It would be possible to do this, but it is not that simple because the entire production process must be considered for a solid COO analysis. However, the cost-saving potential is considerable, because the costs for the silver metallization yield a significant share of the total costs.”

“Further activities at Fraunhofer ISE will focus on further reducing the printed finger width and evaluating the reliability and long -term stability of the new metallization in the module,” he concluded.

The same research team has recently also shown how silver consumption for HJT cells to reduce screen prints using low temperature paste based on AG-Coate CU or Pure CU particles. Their findings are available in the newspaper “Transition from SHJ sun cell printed on silver to copper“Which was recently published in Solar energy materials and solar cells.

This content is protected by copyright and may not be reused. If you want to work with us and reuse part of our content, please contact: editors@pv-magazine.com.