Vegetable and sperm oil are increasingly being used to insulate electrical transmission equipment. The IEC offers the standards for these environmentally friendly insulating liquids.

Electricity is used in developed countries without even thinking about it. It is used for almost any action, from switching the lights in the morning to watching television in the evening before the alarm is set for the next day. It is one of the characteristics of the fully electrical and connected society: the assumption that electricity will always be there to meet every need. But to make that happen, many people who work in utility companies and industry have to ensure that countless safety and performance standards are met – and most of them are published by the IEC.

Such a carefree attitude towards electricity does not exist in emerging countries, where people are more aware of its benefits. But as electric current is used around the world, as people who had access to a source they had to do earlier, IEC security and performance standards are just as essential.

Safety due to liquid insulation

One of the areas that rarely reaches the headlines, but that is nevertheless essential for our safety, is to ensure that the electricity transmission network is well insulated. All electrical equipment must be protected with a non-conductive material or substance that means the power of electric current and prevents short circuits and electric shocks.

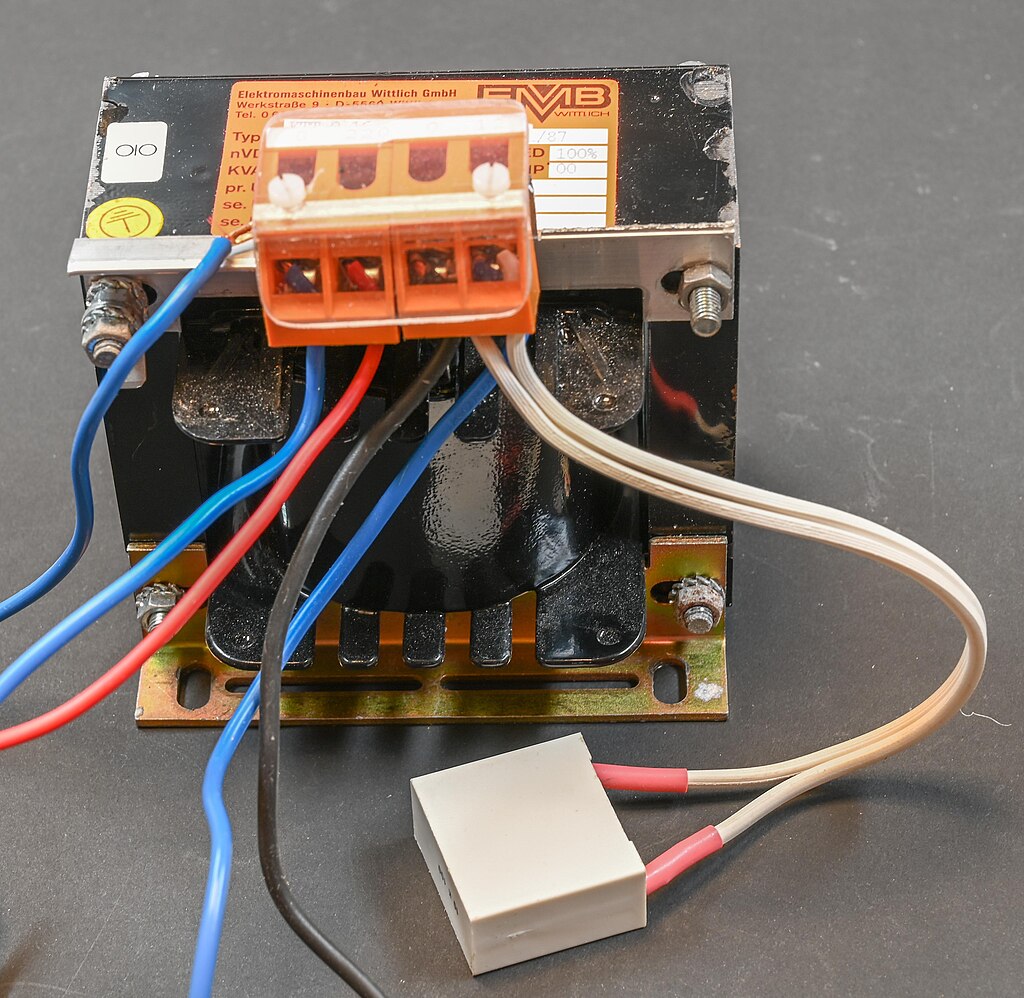

Liquid insulation is one of the ways to ensure that transformers – which convert electrical power from high voltages to lower voltages – remain safe. Liquid is used because of the cooling effect, which is essential for the energy-efficient operation of the equipment, which means it can take longer. It is estimated that several billion lin isolating liquids are used in transformers worldwide.

Insulating liquids have been used since the early 1900s when electricity was used. According to this article in ResearchSince those early days, the most important insulating liquid in industrial energy systems has been on petroleum-based oil, so-called mineral oil, because of the good aging behavior, low viscosity, ready available and low costs. Crude oil was discovered in the mid -19th century and only preceded the arrival of electricity.

Even in those early days, however, part of the inconveniences of mineral oils were clear. They were very flammable and turned out to be dangerous to use at locations where fires could easily break out. The industry then started using polychloor bifenyl (PCB) -based insulating liquids from the 1930s. However, PCBs are toxic and persistent chemicals.

According to the Communications Workers of America unionThose employees who can come into contact with these chemicals, PCBs are not biodegradable, which means that they do not separate or separate into chemical regulations, and can cause cancer and other serious health problems for people and animals, as well as causing significant environmental benefit/pollution.

PCBs are therefore forbidden for use in most countries to play in the late 1970s-yearly ’80s in the EU but still in transformers they used before they were banned. According to the chairman of the IEC technical committee Those insulation fluids for electrical equipment, Ivanka Atanasova-Hoehlein standardizes: “There are constant efforts in many countries to identify and safely remove PCB-containing equipment.”

Moving to environmentally friendly liquids

The desire to use safer and environmentally friendly liquids has scientists encouraged alternative solutions to work out – a movement that has been accelerated in the last 40 years, because populations have become increasingly aware of pollution risks and how to maintain the environment.

Global Market Research Company MRFR Estimate that the bio-based transformer oil industry, which is currently worth around the USD 1.6 billion, is expected to grow by 7.3 % in 2032. Bio-based fuels currently represent approximately a 35 % share in the market.

Sustainable, renewable, biodegradable and environmentally friendly insulating substances are used, although their costs remain higher than conventional liquids. Alternatives to mineral oils include vegetable or sperm oil that are bio-degradable and much less toxic to the environment. They have some disadvantages according to this researchIn particular more vulnerable for oxidation.

Synthetic esters are also an option, because they are also biodegradable and do not broadcast polluting gases while burning. Atanasova-Hoehlein says that they also “have good oxidation stability, which makes it possible to use equipment such as traction transformers for rail systems”. They also have disadvantages because they are more expensive than vegetable and sperm oil and are derived from petroleum sources, which means that they have a higher carbon productive print.

Other alternatives are based on bio-based hydrocarbon, derived from biogenic waste and gas-to-liquid (GTL) insulating liquids. “These belong to the group of unused mineral oils, as specified in one of one of one of them Our standards“Atanasova-Hoehlein describes. Another alternative is to recycle used mineral oils.

Standards are crucial for environmental and safety reasons

IEC 60296 is generally recognized if the standard that controls the use of mineral oils for insulation, including bio-based hydrocarbon fluids, produced by gas-to-liquid processes. The latest edition of this standard was published in 2020 and is also about recycling those conventional oils. The IEC has issued the most required safety and performance bends in the area and is increasingly focusing on environmental requirements. Natural esters such as vegetable oils are standardized in IEC 62770While synthetic is specified in IEC 61099of which a third edition is currently being developed.

While we go to a completely electric world, insulating liquids become more essential than ever before, while we achieve stricter environmental goals, using IEC standards.

Author: Catherine Bischofberger

The International Electrotechnical Commission (IEC) is a global, non-profit membership organization that brings together 174 countries and coordinates the work of 30,000 experts worldwide. IEC international standards and conformity assessment are based on international trade in electrical and electronic goods. They facilitate access to electricity and verify the safety, performance and interoperability of electrical and electronic devices and systems, including consumer devices such as mobile phones or refrigerators, office and medical equipment, information technology, electricity generation and much more.

The views and opinions expressed in this article are the author, and do not necessarily reflect it by PV -Magazine.

This content is protected by copyright and may not be reused. If you want to work with us and reuse part of our content, please contact: editors@pv-magazine.com.