Researchers in China have manufactured a Perovskiet-Topcon sun cell with a top perovskiet device using a self-assembled monolaag aimed at improved cell stability. The tandem cell achieved a high filling factor and a certified efficiency of 30.9%.

A group of researchers led by Zhejiang University in China has manufactured a perovskiet-top-tandem solar cell with an inverted perovskiet cell with a self-assembled monolaag (SAM) who is said to improve the thermal stability of the cell.

Reverse perovskiet cells have a device structure that is known as “pin”, where hole-selective contact P is at the bottom of intrinsic perovskiet layer I with electron transport layer N at the top. Conventional halogenide perovskiet cells have the same structure but vice versa – a “NIP” layout. In NIP architecture, the solar cell is illuminated by the electron transport layer (ETL) side; In the PIN structure it is enlightened by the surface of the hole transport layer (HTL).

The Scientists Explained that electron density within the Sams can be modulated to shift the interfacial energetics between the sam and perovskite layer, which results in a “More Versatile and controlled approach” to optimizing energy alignment in the perovskite a halar also also also also also also albe hill also also also albe hilly also eagle also albe hilly also also eagle also also eagle also also albe hilly also also albe hilly also albe ere havy also eagle also albebles also albe eagle also albebles alsobles alsobles alsobles alsulence alsulence alsulence alsulence alsulence alsulence albebles alsulence alsulence alsulence alsulence alsulence alsulence alsulence alsulence alsulence alsulence albeberly Stability of the Wide-Bandgap Perovskite Film.

The team built the upper perovskiet cell with an indium tin oxide (ITO) layer, the SAM, a nickel oxide (NIO) layer, a perovskietbsorbator with an energy band of 1.68 EV, a lithium fluoride (lif) layer, an electron transport layer (ETL) based on Buckminsterfullerene (C60) and Tinoxide (SNO2),),, A transparent back contact made from indium zinc oxide (IZO), and a silver (AG) metal contact.

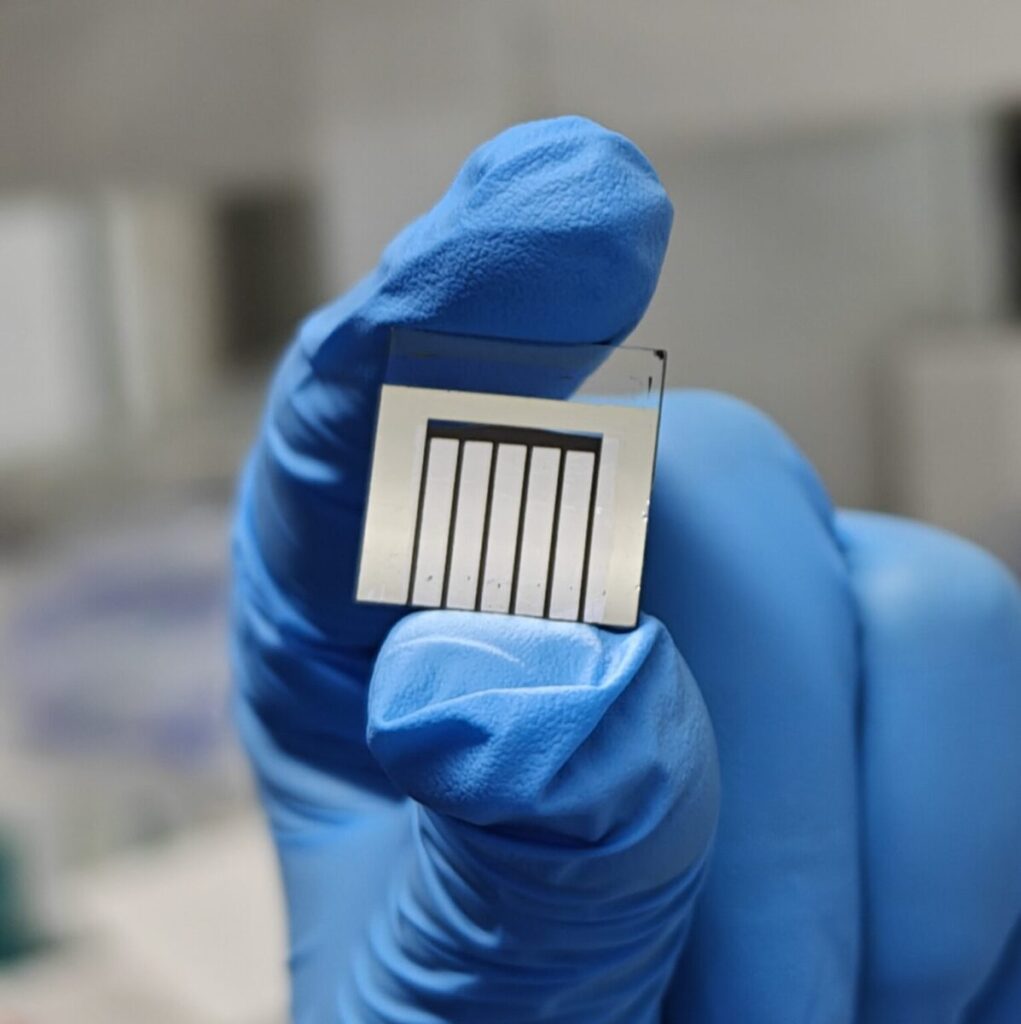

Image: Zhejiang University, Nature Communications, CC BY-NC-ND 4.0

Tested under standard lighting conditions, the upper perovskiet cell turned out to have a power conversion efficiency of 22.8%, an open circuit voltage of 1.24 V and a “high” filling factor of 84.3%. It also turned out to retain more than 99% of the initial efficiency after 400 hours Maximum Power Point Tracking at 60 C.

With the help of this cell, the researchers built a 1 cm2 Tandem device including a standard Topcon sun cell as a lower device.

This cell achieved an internally measured efficiency of 31.1% and a certified efficiency of 30.9%, with the Chengdu Institute of Product Quality Inspection Co., Ltd. National Photovoltaic Product Quality Inspection & Testing Center that has verified the result.

It also achieved an open circuit voltage of 1.88 V and a short -circuit current of 20.0 mA cm-2and a “high” filling factor of 82.6%.

The researchers claimed that these figures demonstrate the reliability and potential application of the inductive effect modification strategy for broadband gap perovskite solar cells with wide bandgap-perovskiet.

“The results emphasize the possibility of SAM’s rational design by using the inductive effect to achieve favorite interfacial energy with Wide-Bandgap Perovskiet,” they emphasized. “We believe that this strategy is promising to contribute to the commercialization of perovskiet and perovskiet-top tandem tandem solar cells.”

The new cell concept was presented in the paper “Inductive effects in molecular contacts can enable broad band gap perovskiet cells for efficient perovskiet/topcon tandems“Which was recently published in Nature communication.

In July, other researchers from Zhejiang University in China announced that they had developed an inverted perovskite solar cell for the first time on the basis of a hybrid perovskiet material that allegedly improves the stability of the device and at the same time offers excellent efficiency levels.

This content is protected by copyright and may not be reused. If you want to work with us and reuse part of our content, please contact: editors@pv-magazine.com.

Popular content