Qcells said his perovskiet/silicon tandem solar modules have passed various critical stress tests for the reliability of solar cells.

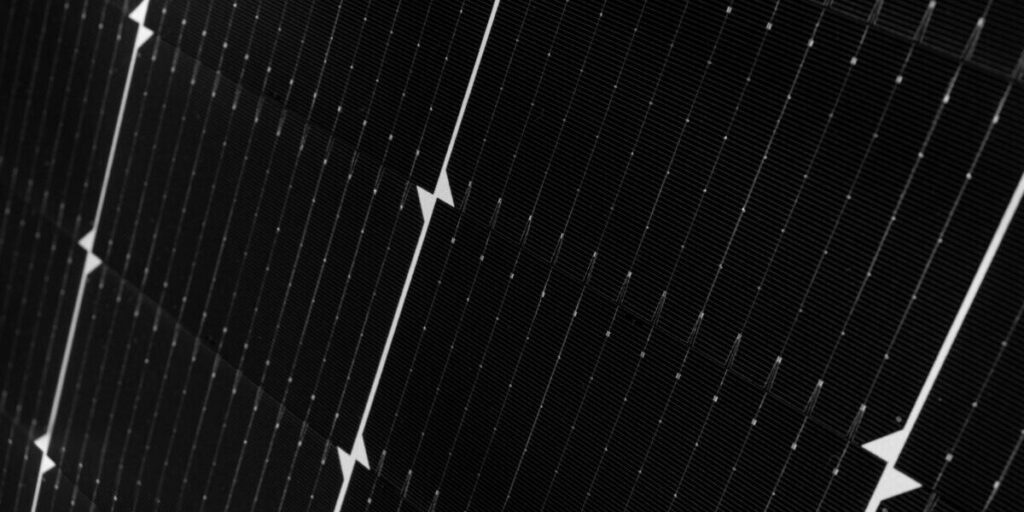

The tested modules are based on the company’s internal perovskiet technology as a top cell, with its own Q.Antum silicon technology as a soil cell.

The modules have passed several IEC standard stress tests, including UV pre-conditioning at 15 kWh/m², 200 thermal cycles, 10 moisture freezing cycles and 1000 hours of moisture heat. Tüv Rheinland has verified the results independently.

Danielle Merfeld, global Chief Technology Officer at Qcells, said that this marks the first report of dental modules that have passed such stress tests.

“The tested cells and modules are typical devices of our pilot line of research and development in Germany and are manufactured by only using processes that are possible for mass production, ”explained Fabian Fertig, head of Tandem -R & D at Qcells Germany.

The company added that it has passed the most critical stress tests for the reliability of solar cells, despite tandem-specific energy measurement limits. “Qcells has shown that tandem technology can now meet the performance benchmarks that form the basis for commercial acceptance,” said it.

In December 2024, Qcells won a world record 28.6% Efficiency For a commercially scalable perovskiet/silicon tandem solar cell.

This content is protected by copyright and may not be reused. If you want to work with us and reuse part of our content, please contact: editors@pv-magazine.com.

Popular content