An international research team has observed a significant increase in series resistance in Topcon sun cells treated with Leco after temperature and bias treatment. The scientists said that they now have to conduct further research into its impact on cell efficiency, reliability and bankability.

A group of researchers from the University of Oxford in the United Kingdom and the Chinese metallization pasta specialist Changzhou Fusion New Materials has identified a new failure mode in Topcon-Zonnemodules that have been made through the so-called laser-improved contact optimization process.

The process is carried out after firing the metallization paste and includes scanning a laser over a crystalline silicon cell while it is under inverted bias. The result is that free carrier electrons are forced between the metal contact and the silicon, creating a new structure on the edge of the contact and drill-emitter layer surface-a power-supplied contact (CFC). Based on the new CFC structure, topcon cells that undergo the Leco process show no contact resistance after thermal bicycles.

“This process induces a localized high power density on the contact interface, thereby promoting interdriffusion between silver and silicon materials, reducing contact resistance and improves cell efficiency,” explained scientists, and noted that efficiency winsts can reach up to 0.6%. “Leco is especially effective in topcon cells, where it helps to achieve a low contact resistance while maintaining good interface passivation to the P-Side, which improves open-circuit voltage and filling factor at the same time.”

The research team in particular investigated a breakdown in series resistance that influenced the topcon cells after temperature and bias treatment. It also explained that his work is based on earlier scientific research that shows that applying a current during the thermal process can increase the resistance of the series ‘Due to an order of size’.

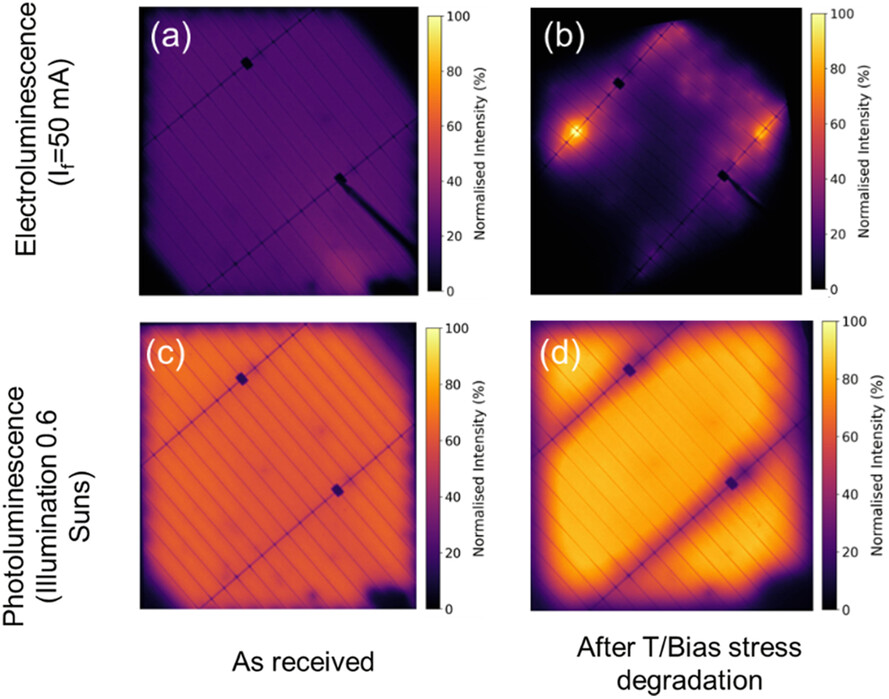

In situ IV monitoring, the academics carried out during a 400 ° C glow process from both conventional and Leco-treated topcon sun cells and applied independent biascycli in a forward-looking-reversse order. In addition, they used electroluminescence (EL) and photoluminescence (PL) to assess the spatial distribution of series resistance and cell massification quality.

During the first cycle of forward bias, the scientists saw constant growth in series resistance, while in reverse bias they found a slight decrease in series resistance.

“Such relegation is in line with previously reported findings in the literature, which attribute the resistance increase to the passivating of the silver/n+-Polysilicon interface, “they specified.” When analyzing the Leco-Topcon cells, the forward biascondition leads to a decrease in series resistance, which is the opposite of what was observed in conventional topcon cells. The most amazing is the inverted bias in Leco-Topcon seriously demolished the series resistance, so that it increases more than two orders of size for 30 minutes. “

The researchers warned that, if not tackled, the observed series resistance breakdown could influence both the performance and the economic viability of cells treated with Leco. “Further research is required to understand the microscopic nature of this reliability problem and to investigate potential mitigation strategies for improving stability under operational conditions,” they concluded.

Their findings are presented in the study “A failure mode that influences the reliability of very efficient topcon sun cells treated with Leco“Published in RRL Solar.

Last year, scientists from the Australian University of New South Wales (UNSW) and the Chinese Canadian PV module manufacturer Canadian Solar showed the demolition of industrial topcon sun cells that was subject to accelerated test conditions of 85 ° C and 85% relative humidity (DH85). The primary demolition mechanism in this study was a significant increase in the series resistance.

This content is protected by copyright and may not be reused. If you want to work with us and reuse part of our content, please contact: editors@pv-magazine.com.