The reach of cost-competitive green hydrogen production is crucial for the transition to a net-no-green greenhouse gas emission economy. Green hydrogen offers a viable solution for the low-carbon industries that are among the heaviest polluters, including metal production, heavy transport, chemicals and energy-intensive sectors that currently depend on fossil fuels. It plays a central role in Power-to-X (PTX) technologies and serves as a important raw material For producing synthetic fuels and chemicals, such as e-methanol, e-amammonia and e-cerosene.

In the metal industry, which is good for around 7% of Global Co2 Emissions, direct reduction of iron using green hydrogen can replace blast furnaces that would eliminate the carbon dioxide emissions from the reduction process. For heavy transport where direct electrification is not possible, green e-fuels based on hydrogen can offer an attractive option to reduce the carbon footprint. For the chemical industry, hydrogen is already used on a large scale as a raw material for many processes such as ammonia and methanol production. Replacing the currently used hydrogen based on natural gas with green hydrogen would lead to a significant reduction of emissions.

In addition, including water electrolyzers in the future electricity grid can be crucial to improve flexibility in two important ways. Firstly, the green hydrogen produced can act as an energy storage for intermittent renewable energy and secondly the electrolyzer devices work as a flexible wealth tax thanks to their reasonable broad working range. Both aspects will be extremely valuable in stabilizing a renewably dominated schedule.

However, dimensioning and controlling green hydrogen plants that depend on intermittent electricity from renewable sources is not a trivial task. The dynamic effect of electrolyzers is limited By various factorswhich – in combination with the intermittentie of the diet – can significantly influence the production costs of the hydrogen.

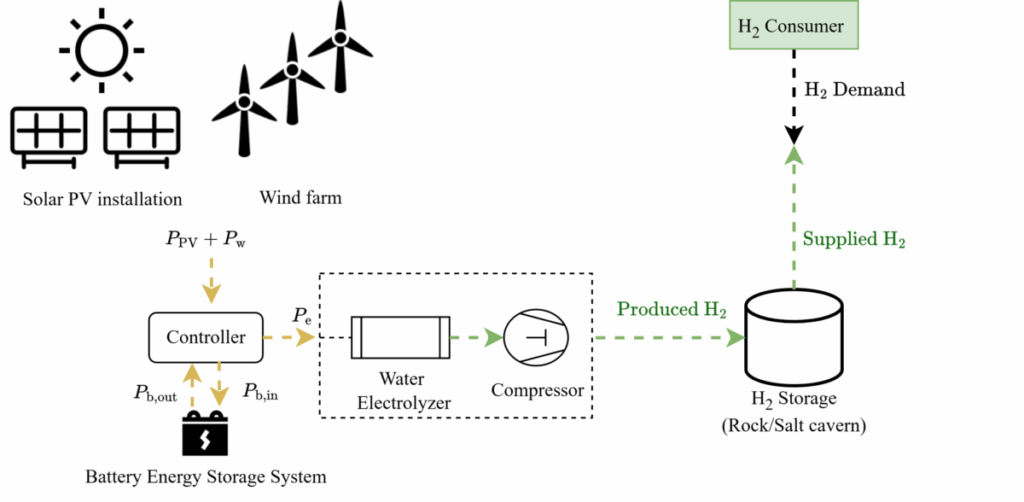

Researchers by Lut University have investigated the optimization of green hydrogen production plants by at the same time considering both the control and the dimensioning of plant components, which shows that this approach can considerably reduce the production costs of hydrogen production. The optimization method Consists of a simulation model of an off-grid electrolyzer plant that uses solar PV, wind energy and batteries for short-term storage.

The optimization results showed that the use of energy storage batteries improves the stability of the electricity supply and reduces the risk of fast electrolyzer closures during periods without solar PV or wind energy production. However, the battery price must fall under 0.30 €/W Cost -effective solution for overnight energy storage.

The demolition of the components, replacements and operational costs (OPEX) also influence the optimum dimensioning and control of a hydrogen plant, in particular given the expected lifespan of such facilities of 25-30 years. For an off-grid hydrogen production plant in the southeast of FinlandWind energy was only identified as the most cost -effective configuration, with the level of hydrogen (LCOH₂) possibly fell to € 2/kg in 2030. However, by 2035-2040, projected price scenarios suggest that the recording of solar PV and batteries for short-term storage will become the optimum solution in the short term.

These findings reinforce the case for green hydrogen as a viable and more and more competitive alternative, in particular in comparison with hydrogen produced from natural gas through steamethane reform (gray hydrogen), which usually costs between € 1-1.5/kgor with carbon collection and storage (blue hydrogen), Where the costs rise to around € 1.5-2/kg.

A Recent publication Focuses on Baseload green hydrogen supply using an off-grid electrolyse factory. The study has optimized the plant control and component capacities, including hydrogen storage in geological caves, to minimize the LCOH₂ for a lifespan of 30 years, while a uninterrupted hydrogen supply is guaranteed for a simulated end user.

The techno-economic optimization showed that, for a given electrolyzing capacity, there is a specific demand for demand that minimizes the LCOH₂. In particular, the most cost-effective factory configuration among the 2025 components combines price scenario Zonne-PV and wind farms for generating electricity, together with a short-term battery system. This indicates that, for an optimal plant, which is designed to meet a baseload hydrogen demand, including both batteries and solar PV minimizes the costs of the hydrogen supply.

Image: Lut, adapted from Ibáñez-Rioja et al.

When the nominal capacity of the electrolyzer has been determined and the demand speed of the hydrogen exceeds the optimum value, the system reaches a point where the electrolyzer factory must work continuously. This requires oversizing of the solar PV, wind farm and batteries, which increases the LCOH₂. Conversely, if the demand of the hydrogen is too low, the hydrogen production capacity of the electrolyzer becomes excessive for demand, reducing the economic return of the plant, which further increases the LCOHither.

Another important finding of the study Wash the difference in plant design when striving for a baseload hydrogen, compared to a hydrogen plant that is only optimized for minimizing production costs under the assumption of fully flexible demand for hydrogen. The results indicate that maintaining a strict baseload demand can increase the production costs of the hydrogen by a maximum of € 0.75/kg (+31%).

These results underline the importance of further research to whether it is more cost-effective for green hydrogen producers or consumers to introduce greater flexibility to the production of hydrogen or to be better in line with the intermittentie of renewable energy. Limitation of plant control and design to a fixed hydrogen demand shifts the full flexibility burden to the production side. The increasing flexibility on the demand side can reduce the required hydrogen storage capacity, battery energy capacity and the need to reduce the production of renewable power production, which ultimately reduces the production costs of green hydrogen.

The solar PV and wind energy data used in the studies were collected from southeastern Finland, so that the results may apply to other Nordic regions with similar weather conditions. Nevertheless, given the constant transition from Finland to Netto-Nulemissions, Solar and wind energy is expected to become the dominant sources of electricity generation. This energy scenario emphasizes the importance of accurate dimensioning and regulating hydrogen production plants, in particular in the trust in intermittent renewable energy sources, because this can significantly influence the costs of the hydrogen supply.

Currently, the research team is at Lut University works on the Future commercialization of these optimization methodsWith the aim of developing a software tool to support the implementation of green hydrogen plants.

Authors: Alejandro Ibáñez-Rioja, Pietari Puranen, Lauri Järvinen, Dominik Keiner, Antti Kosons and Jero Ahola.

This article is part of a monthly column of Lut University.

Research into Lut University includes various analyzes with regard to strength, warmth, transport, desalination and negative CO2 Emission options. Power-to-X research is a core subject at the university, integrated into the focus areas of energy, air, water and company and society. Solar energy plays a key role in all research aspects.

The views and opinions expressed in this article are the author, and do not necessarily reflect it by PV -Magazine.

This content is protected by copyright and may not be reused. If you want to work with us and reuse part of our content, please contact: editors@pv-magazine.com.

Popular content