New research from the University of New South Wales has discovered that the special injected metallization (JSIM) technology, developed by the Chinese manufacturer Jolywood, can considerably increase the efficiency of the Topcon sun cell. The scientists described exactly how laser-supported fires improves cell performance and reportedly fill in critical gaps in the top-conver cell optimization.

Scientists from the University of New South Wales (UNSW) in Australia have investigated how effectively the laser-assisted firing process developed by Chinese solar module manufacturer Jolywood, the so-called Jolywood Special Injected Metallization (JSIM), enhances the efficiency of industrial-scale TOPCon solar cells by reducing Si-metal contact recombination and have found the Manufacturing step can increase cell efficiency by approxroximately 0.6% absolute compared to the baseline single-step firing process.

“The results show that JSIM is easily applicable in large -scale production lines and manufacturers offers a robust route to exceed 25% efficiency without significant extra costs or complexity,” said the corresponding author of the research, Bram Hoex, said PV Magazine. “This is particularly relevant to hot, humid climates, helping industry in reaching bankable, highly efficient modules.”

The researchers emphasized that laser-supported shooting technologies such as JSIM and the so-called laser-improved contact optimization (LECO) developed by Qcells in South Korea an extra laser scan process in combination with an applied inverted bias, after an initial co-firing step. It is said that this step is able to increase cell efficiency, but also considerably improve the corrosion resistance of Topcon sun cells

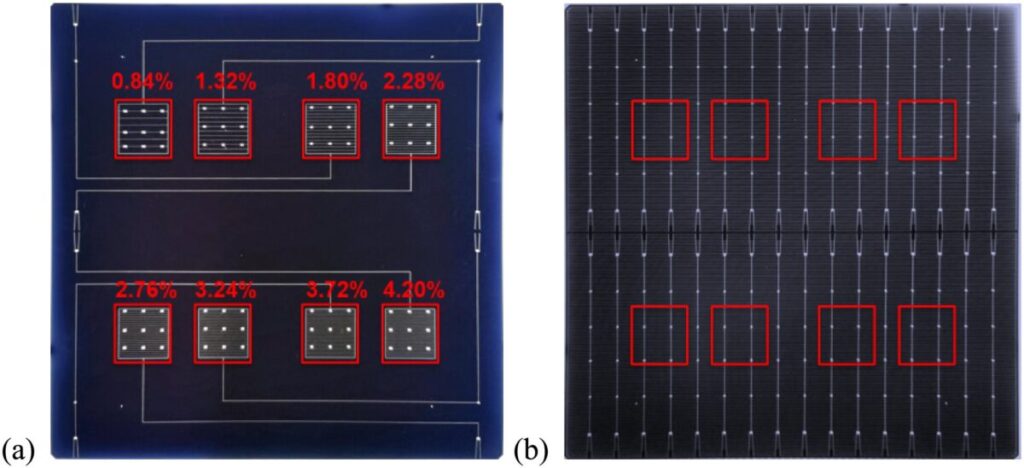

In their analysis, the academics compared the performance of JSIM with those of other baseline (BL) single-step co-firing processes. They used ultramodern cells of the high-volume production of non-known solar manufacturers, where the JSIM cells use a homogeneous emitter structure and the BL cells with a selective emitter (SE).

Image: Image: Unsw, Progress in Fotovoltaïschen, CC by 4.0

For the JSIM cells, the research team used one Silicon monoxide (SIOX) Tunneling Low and a poly-si layer for the back using plasma oxidation and plasma assisted in situ doping deposits (POPAID), followed by a buffered oxide-sets (BOE) cleaning process. They also used passivation saluminum oxide (ALOX) layers that were deposited via Atomic Layer (Ald) and silicon nitride (sinX ) Layers deposited by plasma-improved chemical vapor deposits (PECVD) at the front, as well as a PECVD SinX Passifying layer at the back.

With regard to the BL devices, the group used a traditional metallization process with a commercial aluminum silver (AL/AG) print pasta for the screen and a traditional industrial shooting process with one step. “For comparison: the JSIM monsters used a specialized AG front pasty and underwent shooting at a temperature of approximately 30 ° C, followed by the JSIM process, which has recorded a laser line scan procedure in combination with a reversed bias,” explained it further.

The analysis showed that the JSIM process absolutely improved the performance of Topcon sun cells by around 0.58%. ‘Detailed quantification of electrical parameters such as contact resistance, line resistance and metal contact combination revealed substantial reductions for and behind metal short-circuit density, “stated Hoex” Extensive quokka 3 simulations validated our experimental findings and emphasized Patrils, with an additional improvement opportunities, with an additional prospective patrons, with an additional improvement-portrayal opportunities, “

Looking ahead, the researchers want to optimize the process to improve the bulk resistance of the cell and the quality of the surface passion.

Their findings are available in the study “Solar cells of higher efficient topcon cells in mass production made possible by laser-supported shooting: advanced loss analysis and potentially in the short term efficiency“Which was recently published in Progress in photovoltaic.

Earlier research on Topcon by UNSW showed the vulnerability of Topcon sun cells to contact corrosion and three types of Topcon sun module errors that were never detected in perc panels. In addition, UNSW scientists investigated the breakdown of topcon sun cells induced by sodium under exposure to damp heating and Relegation mechanisms of industrial-concon-zonnemodules encapsulated with ethylene vinylacetate (EVA) under accelerated damp conditions.

This content is protected by copyright and may not be reused. If you want to work with us and reuse part of our content, please contact: editors@pv-magazine.com.

Popular content