German automation specialist ACP systems developed an advanced robotics solution that integrates image processing to process a series of waferrottes and tolerances within a vapor deposits process for a manufacturer of space -sun cell technologies. The requirements include a compact design, pre -casion within 0.1 mm and automated quality control of the wafer handling.

The ACP systems of the German industrial equipment ACP systems has integrated a vision-assisted robotics solution for handling in the Wafers in coating systems made by Singulus technologies established in Germany and implemented by Azur Space Solar Power, high-quality manufacturer and high-quality, high-quality manufacturer and high-quality, high-quality, high-quality manufacturer Terrestric concentrator systems (CPV) in Germany.

The manufacturer with multiple junction solar cells required a fully automated solution that was integrated into a plasma-improved chemical vapor deposition (PECVD) process to improve productivity, but that would also be accurate and carefully high-quality solar cells built on Germanium-Substraten, according to ACP systems.

The new solution was devised to ensure that the specified positioning accuracy of +/- 0.1 mm in the nests of the workpiece carriers was met and that both the production tolerances of the bearers and contraction were caused by cooling during loading.

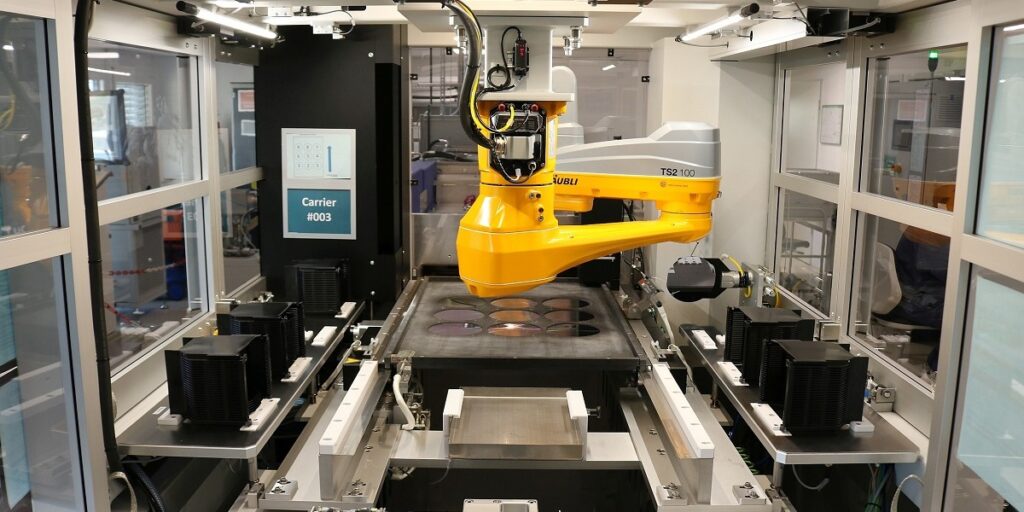

To take on the challenge, an intelligent, vision-assisted wafer handling solution an industrial selective compliance-articulated robot arm (Scara) robot in support of two-sided coating was developed. It was mounted and integrated into the cassette loading area of the Singulululs Technologies PECVD systems.

“The new system was commissioned in June 2024 and since then there have been no handling -related wafer fracture” PV Magazine.

The solution includes at least two subsystems of the camera-de Cognex Vision Pro Machine Vision software and the Scara robot. The latter has an arm range of 1,000 millimeters that takes the waffles from the cassettes and reliably and accurately places them in the few hundred micrometer larger carbon fiber nests of the workpiece carriers, next to other tasks.

The robot arm is equipped with a flat vacuum grab that can be quickly exchanged to process waffles of different sizes. The system also has a Flipper station to change the solar cells on both sides. “Depending on the cell size, the 1,000 mm x 600 mm carriers can contain four, nine or 16 waffles,” said ACP Systems.

A 12-megapixel camera detects the exact position of the waffles on the background lighting table and sends information during the process to the Machine Vision software, which offers control and calculation capacity to make precise positioning and treatment possible, even if the waffles and cassettes differ from the original size, shape or thickness. For example in the case of thermal contraction due to cooling after the coating process at temperatures up to 350 C.

Finally, a camera system is used for quality control to ensure that the edges of the waffles are released before the coated solar cells are placed back in the cassettes.

ACP Systems founded in 1997, offers technology to Solar PV; Electronics, semiconductor, automotive, medical and pharmaceutical production industry. It recently developed the Quattroclean Snow Jet Cleaning System that is integrated in equipment made by Germany -based sciprios for perovskite solar cells and organic PV (OPT) manufacturing.

This content is protected by copyright and may not be reused. If you want to work with us and reuse part of our content, please contact: editors@pv-magazine.com.

Popular content