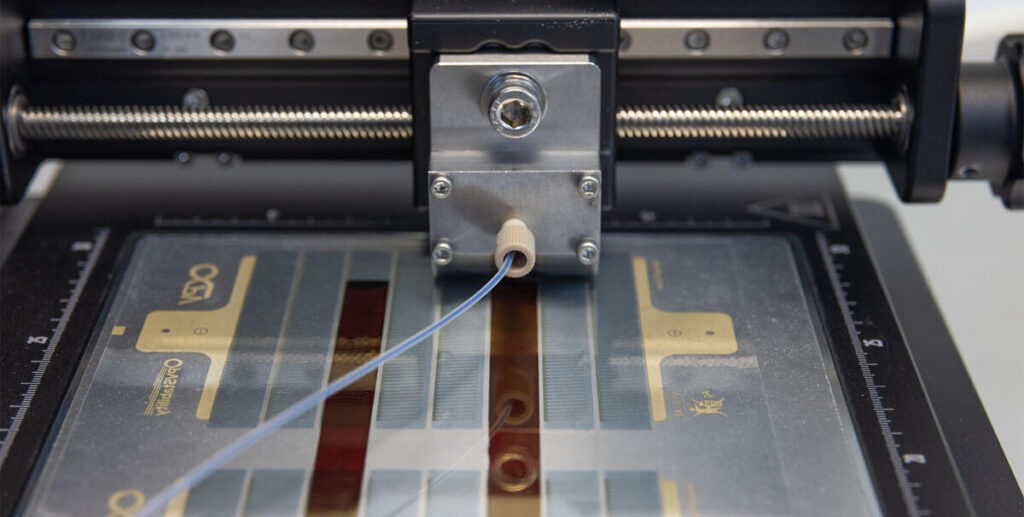

The adjustable, compact leaf coater supports coat racing from 1.2 mm/sec to 33 mm/sec.

InfinityPV, a Danish supplier of printed electronics equipment, has launched a final-DIE coater to offer thin-film PV researchers with a compact, configurable plate coater that is suitable for organic and inorganic solar cell technologies.

“Our final DIE coater provides exceptional coating uniformity for films on nanometer-to-micrometer scale, which offers a wide range of liquid formulations. It is aimed at researchers who strive for precision and reproducibility,” J, “JOn Carlé, the head of the sale at InfinityPV, said PV Magazine.

The equipment is supplied in two sizes, Mini and Pro, which support coating widths of 100 mm x 280 mm and 160 mm x 280 mm. Both models have an adjustable coatation speed vary from 1.2 mm/sec to 33 mm/sec, 110-240 VAC-business assets and a compact form factor that is dashboard box and fumhood-compatible.

The smaller unit is 440 mm x 360 mm x 400 mm, with a weight of 22 kg, and the larger one is 440 mm x 420 mm x 400 mm, with a weight of 24 kg.

The InfinityPV Slot-Die Coater Standard Hot Plate supports the temperatures of up to 100 C. An optional hot plate with high temperature can reach 140 C.

All models are equipped with a spray pump that offers precise ink -beet adjustments for optimum delivery of both organic and inorganic formulations, according to the company.

Different add-on modules or interchangeable components are available for knife coating, pen, beam and flexo printing processes. A heated lock that head is also available as an option.

The Product is Avarable Directly via The Company’s Website and From Resellers, Such As Sangyo GmbH Based in Germany, MSE Supplies Based in The United States, Vector Technologies Ltd Based in Greece, Gaia Science Based in Austapore, Ezzi Vision. Vision. Based in Japan, Wonwoo Systems and Dong-ah Trade Corp. Based in South Korea, and Yeada Photonelectric Based in China.

Short Youtube -video Emphasizes how researchers can use the equipment.

InfinityPV was founded in 2014 and makes a series of products for Solar PV manufacturing and characterization, including inks and software. It also offers equipment for the manufacture of printed batteries, fuel cells, OLEDs and sensors.

This content is protected by copyright and may not be reused. If you want to work with us and reuse part of our content, please contact: editors@pv-magazine.com.