South Korean researchers have manufactured a copper Indium Gallium-selenide (CIGS) solar cell with a 90 μm thick UTG supplied by the unique technological integral technology. The device uses a cadmium -free buffer layer made from zinc oxide and magnesium oxide, instead of cadmium sulfide.

Scientists from the Korea Institute of Energy Research (Kier) have developed a CIGS solar cell with ultra-thin glass (UTG), an rising substrate that is known for its exceptional flexibility and stability.

“We have achieved an impressive efficiency of a record device of more than 17% for cadmium -free flexible solar cells by using an optimized silver alloy strategy at a considerably lower substrate temperatures,” Researcher Donghyeop Shin told PV -Magazine. “This method effectively balances high photovoltaic performance with mechanical flexibility, whereby the briskiness is overcome that usually comes from high temperature processes on UTG substrates.”

The researchers built the cell with 90 μm thick UTG provided by South Korea’s Unique Technology Integral (UTI). With the help of DC microwave, they also contacted Molybdenen (MO) on the cleaned UTG and Silver (AG) layers and the MO contacts.

In a further step they have deposited a 2.0 µm thick Cigs absorber on the UTG substrate via a three-phase co-evaporation process with a multisource dewamer, followed by sodium (NA) and Rubidium (RB) Alkali after deposition treatments.

The cell also uses a cadmium -free buffer layer made of Zinc oxide (ZNO) and magnesium oxide (MGO)Instead of often used cadmium sulfide (CDs), as well as a thin AG for the front layer to make effective grain growth at the lower temperatures required by the use of UTG and protect the cell against transparent conducting oxide (TCO) potential sputter damage.

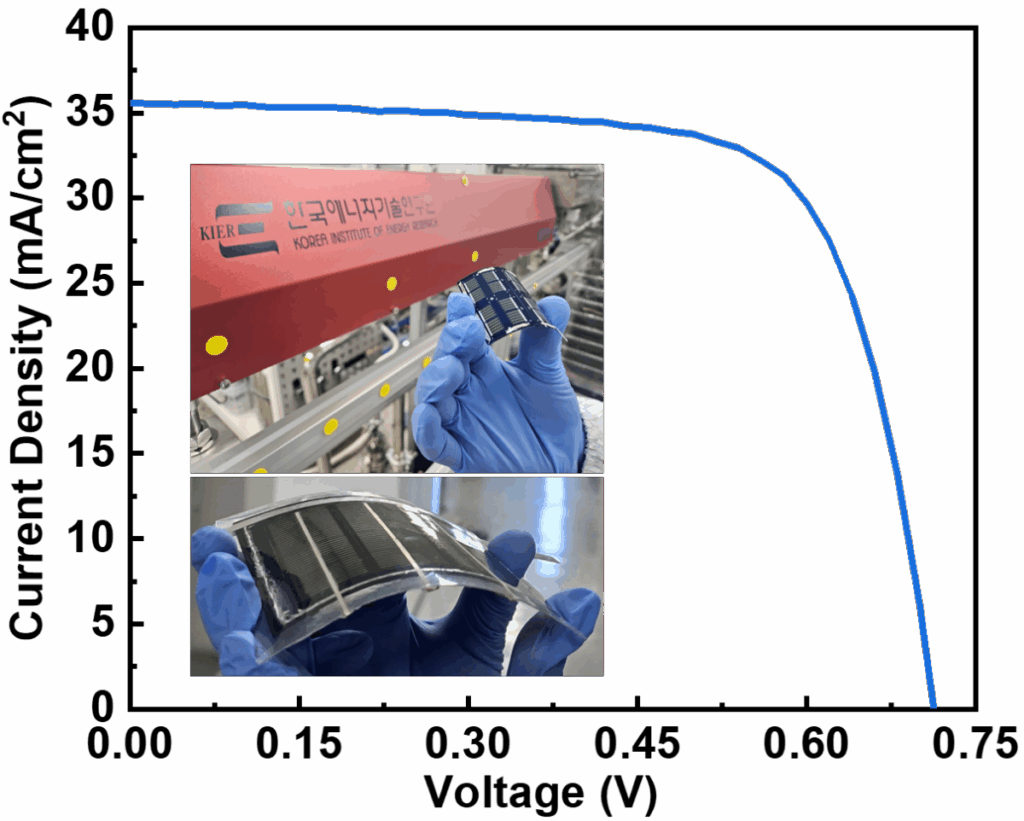

Tested under standard lighting conditions, the device reached a power conversion -efficiency of 17.81%, the scientists said it is in line with those of comparable cells using CDS buffer layers.

“In addition, flexible modules with a size of 60 cm² that have been manufactured with these innovative techniques have demonstrated promising efficiency of more than 10%, which emphasizes their potential for commercial scalability,” Shi said. “The research makes significant steps in improving the performance of flexible solar cells by systematically tackling the interaction between silver uptake and UTG substrates at lower temperatures, while cadmium-free buffer layers are implemented and optimizes intrinsic zinc oxide layers.”

The new cell concept was introduced in the study “Highly efficient cadmium -free CU (in, go) SE2 Flexible thin film solar cells on ultra-thin glass as an emerging substratePublished in the Journal of Alloys and Compounds.

“In general, this work makes an important contribution to the development of environmentally friendly solar technology, with a feasible route in the direction of efficient, scalable and sustainable solar solutions that are well suited for integration in portable electronics, automobile applications and installations of curved surface,” concluded Shin. “Moreover, these flexible solar cells can be used as the lower cell in a tandem device configuration combined with perovskite solar cells.”

This content is protected by copyright and may not be reused. If you want to work with us and reuse part of our content, please contact: editors@pv-magazine.com.