Bert Thin Films has developed a copper pasta for the production of solar cells that prevents the copper from oxidizing during the air fire process, while at the same time it is avoided to make direct contact with the silicon. The new product can be used in existing production lines and with various cell configurations.

US-based Startup Bert Thin Films, Inc. (BFT) has developed a new copper metallization paste for the front for the production of solar cells.

“Our pasta -based pasta can be integrated into existing production lines and formulated to work with the Laser Enhanced Contact Optimization (LECO) process,” said the company’s chief sales officer, Matthew Healy, said PV -MagazineNote that the new product is particularly suitable with the production of Topcon sun cells, where Leco needs twice as much silver.

“The new product was formulated to etched through the silicon nitride layer during the shooting process at peak temperatures of around 600 ° C,” he continued. “The patented formulation prevents the buyer from being able to oxidize during the air viring process, while at the same time the buyer cannot prevent the buyer from making direct contact with the silicon, where the LECO process has completed the contact.”

Healy also explained that any diffusion of the copper in the silicon would damage the cell and emphasized that BTF has verified through accelerated tests that this does not occur with the proposed product, without providing further details.

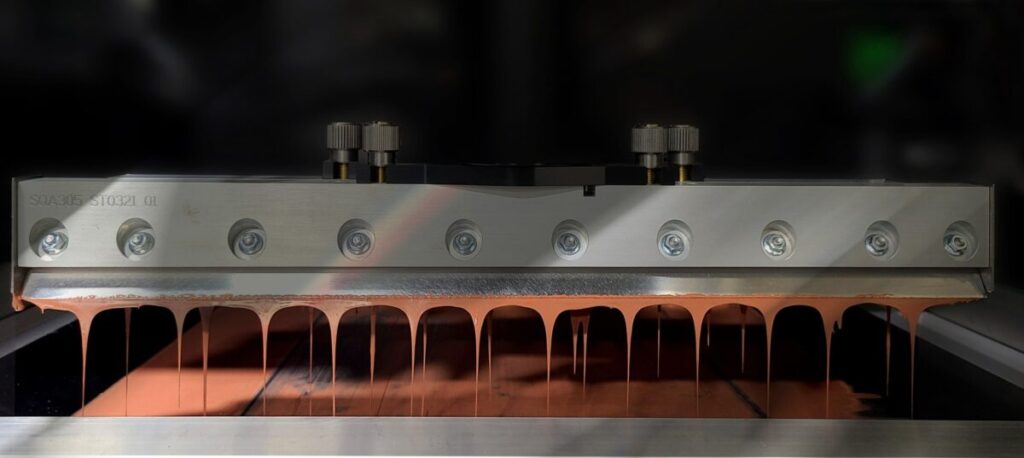

Image: Berth thin movies

The company has also revealed that a topcon cell obtained a power conversion of more than 24%based on an M10 wafer and metallized with the new copper pasta.

“The combination of the pasta formulation and the LECO process has also reached an open circuit voltage that is the same as a sister cell that led silver as the back side contact,” Healy explained. “This shows the viability of replacing a silver paste through a screenshotable air-firing contact on a highly efficient full-sized topcon sun cell.”

The company is of the opinion that, with careful control over the pasta formulation and shooting conditions, the performance of the cell can be further increased. It is currently working with production partners to improve performance and to optimize the processing parameters. Partnerships for scaling the pastas for the needs of the industry are also determined.

“We believe that the product should be ready for the implementation on the pilot scale by 2026,” concluded Healy.

Bert Thin Films, Inc. is located in Kentucky and focuses on making it possible for copper -based solar production over a series of device architectures. It was awarded $ 1 million in financing by the US Department of Energy in 2021.

This content is protected by copyright and may not be reused. If you want to work with us and reuse part of our content, please contact: editors@pv-magazine.com.

Popular content