Researchers from the University of Toledo produced thin film cells with antimones sulfide (SB2S3) with 7.69% power conversion -efficiency after determining the optimum hydrothermic deposition, post -glowing and light weeks. Stability tests showed more than 95% of the initial efficiency after ten months.

Researchers from the University of Toledo in the United States have manufactured antimones sulfide (SB2S3) Thin film solar cells that achieved a champion of wealth conversion of 6.89%, which was subsequently improved to 7.69% after a light weeks.

Research of this specific thin film PV absorber has different drivers. “Given the necessity of cheap, earth-flooded and non-toxic photo voltaic material alternative to other chalcogenidematerials such as Cadmium Telluride (CDTE) and copper Indium Gallium Selenide (CIGS), Antimoon sulfide (SB2S3) is an upcoming material with an attractive candidate material for sun cells. solar cells, ”said Alisha Adhikari, corresponding author of the research, PV Magazine.

In the study, “Process optimization and light soak to improve the photovoltaic performance of antimony sulfide solar cells“Published in ACS Applied Energy MaterialsThe research team specified that performing hydrothermal growth for 225 minutes 135 ° C, combined with post-annealing at 350 ° C for 10 minutes in a tightly controlled process resulted in a device with champion power conversion efficiency of 6.89%, which increased to 7.69% after light weeks.

Adhikari explained that after the optimization of the growth process and post-anneal treatments it would be expected to improve the device performance of the SB2S3 sun cells. “However, we were surprised by the degree of improvement of the device performance of SB2S3 solar cells from 6.89% to 7.69% through light soak,” she added.

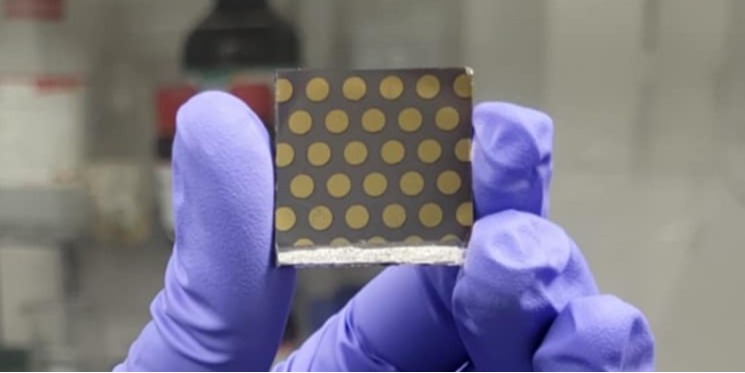

The experimental solar cell pile was as follows: Fluor-doted Tinoxide (FTO) substrate with cadmium sulfide (CDS) coating, the SB2S3 thin film, a Spiro-Tomad hole transport layer (HTL) and Golden (AU) back contacts.

With the help of Atomic Force Microscopy (AFM) imaging, the team saw how surface intervention was flattened after glowing the various samples. “The changes in the grain size and structure correspond to the phase transfer of reddish amorphic metastibnite to black polycrystallijn stibniet, which was confirmed by Xrkgeti fraction (XRD) measurement,” the team said.

The SB2S3 films reportedly had high absorption coefficients with an absorption tape edge of ∼720 Nm, corresponding to a band gap of approximately 1.7 EV.

“We believe that controlling the hydrothermal growth time and post-Annian temperature is crucial for obtaining high-quality SB2S3 films with the desired film thickness, morphology and more preferred grain orientations, which leads to improved performance of solar cells,” said the researchers.

The light that weeks with one -sister radiation at 70 ° C had an expensive 120 minutes. “The improved PCE after soiling the light was mainly the result of raised short -circuit current and filling factor,” said Adhikari.

Moreover, the efficiency after prolonged storage of the slightly driven devices was higher than soaked cells without light. “After 10 months of storage, the cells showed a moderate reduction in the filling factor, a slight decrease in pen circuit voltage and negligible change in short-circuit current, with more than 95% of their initial efficiency,” said Adhikari.

Weeping lights at a suitable raised temperature facilitates the oxidation of Spiro-Toometad, which improves the extraction of holes and transporters. “Our findings show that Light Weeks is an easy and effective approach to improve the performance of SB2S3 sun cells,” the team concluded.

When demanding the future research direction, Adhikari said that the group is planning to explore stable and cost-effective transport layers of gaps to further increase the efficiency of SB2S3 solar cells.

This content is protected by copyright and may not be reused. If you want to work with us and reuse part of our content, please contact: editors@pv-magazine.com.