Fraunhofer ISE researchers say that their newly manufactured Galliumarenide substrates (INP-on-Gaas waffles) can replace Prime Indium phosphid waffles and offer a scalable route to lower the costs.

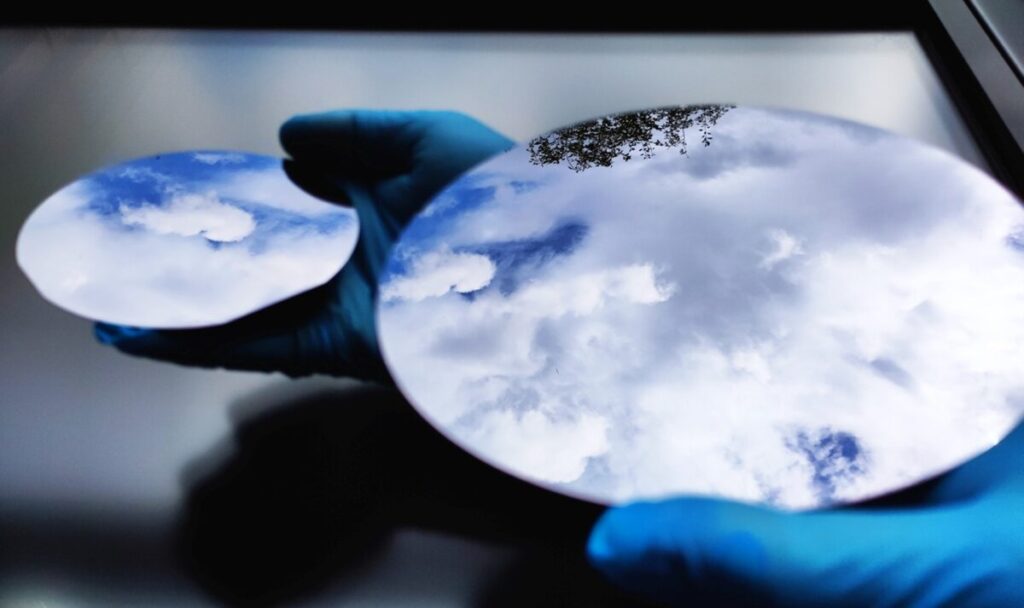

Scientists from the Fraunhofer Institute for Solar Energy Systems Isee have produced Indium phosphid on In Inp-on-Gaas waffles up to 150 mm in diameter.

Working in collaboration with German semiconductor specialists III/V-reclaim, the team developed a process to deposit a thin layer of high-quality indium phosphid on GalliumArsenide.

The team said that the application is challenging because defects occur during the growth of the indium phosphide, which can break down the performance of the final device. To prevent such defects, the team has recorded a series of so-called ‘Metamorfe buffer layers’ and by subjecting the fully grown Inp-op-Gaas wafer to a special chemical mechanical polishing step.

After the surface treatment, the waffles are shiny and have a very low surface line and defect densities under 5*106 cm-2. Fraunhofer Isee said in a statement that their new waffles can effectively replace “classic indium phosphid in various applications, and offers a scalable path to lower costs.”

Carmine Pellegrino, project manager at Fraunhofer Ise, said that companies can use the INP-on-Gaas substrates to produce very efficient devices.

“However, it costs much less than INP and there are no restrictions in terms of scalability to even 8-inch diameter waffles,” Pellegrino added.

The research team has tested the material quality and performance of the waffles against standard indium phosphid substrates and say that the results have been ‘extremely promising’.

“Fotovoltaic cells manufactured on our manipulated waffles reach open circuit tensions similar to reference devices on prime in-in waffles,” said Pellegrino. “The performance is consistent uniform over the entire 6-inch wafer, which makes reliable high yield production possible.”

Pellegrino noted that the production costs of the new Substrates are considerably lower than those of indium phosphid waffles, with potentially savings potential up to 80% in mass production.

“Moreover, our approach bypasses restrictions on the supply of Indium phosphide,” said Pellegrino.

This content is protected by copyright and may not be reused. If you want to work with us and reuse part of our content, please contact: editors@pv-magazine.com.