Manufactured via thermal evaporation, the champion Perovskiet-Perovskite-Silicon triple sunbathing trust solar cell reached an efficiency of approximately 22% after 110 hours of fixed voltage operation under environmental conditions without encapsulation.

A research team led by the German Fraunhofer Institute for Solar Energy Systems (Fraunhofer Isee) and the King Abdullah University of Science and Technology (KAUST) (KAUST) in Saudi Arabia announced using thermal evaporation in the manufacture of an all-in-organization) Perovskite-perovskite-silicon triple junction solar cell.

“This was the first time that CSPBI₂BR was used as the top cell material in one Silicone-based Triple-Junction solar cells with perovskitesAnd also the first instance in which thermal evaporation was used to manufacture the top cell in such a device architecture, “said Yashika Gupta, main author of the research, said PV Magazine.

The CSPBI2BR composition is one of the most stable mixed-halide inorganic perovskiet materials, but problems with manufacture, such as slightly induced halid registration and the risk of solvent damage to underlying layers during the deposition of Top cell, have retained wider use.

“Although all-in-organic perovskikes such as CSPBiBRBBR offer excellent thermal stability, they were not yet integrated into triple junction devices, mainly due to the high glowing temperature after deposition, which would damage the other layers of the three-whom Junction,” explained Gupta.

To overcome these challenges, the research team developed a high tire gap, inorganic perovskietabsorber with the help of thermal evaporation at room temperature, which eliminates the need for glowing after deposition. “In particular, CSPBI 25 were deposited at room temperature without post-anals, films with a 1.88 EV band gap and excellent photo stability,” said Gupta, adding that the materials had “exceptional photoability”, that is, no halide segregation was observed even after 3 hours of continuous illumination.

Stability tests Demonstrable stability, with the device Maintaining performance after more than a year of the storage of the glove box and enduring more than 100 hours of fixed voltage operation at the maximum power point without encapsulation in air.

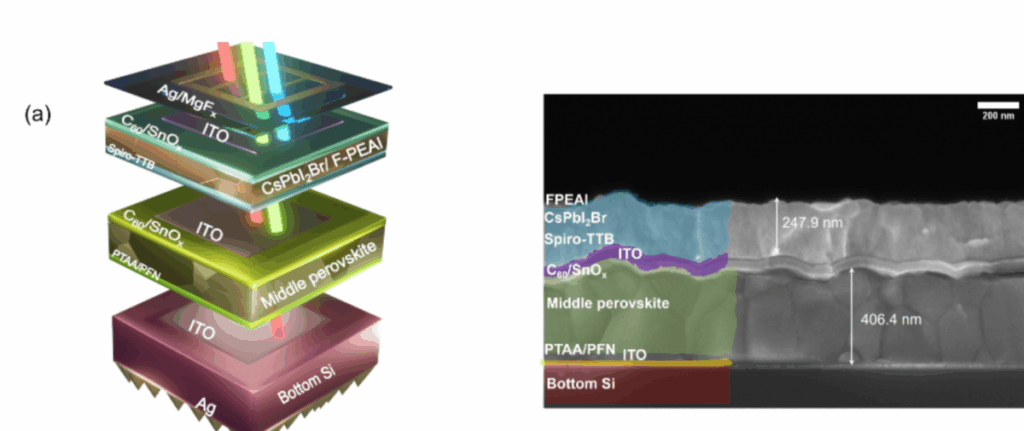

De celstapel bestond uit een silicium heterojunction (SHJ) -cel, indium tin-oxide (ITO), een gattransportlaag (HTL) gemaakt van poly (triarylamine) (PTAA), f-peai passivering (pfn), een absorbervertrouwen op het csfama perovskiet met een energiebandgap van 1,56 ev, een buckminsterfullerene (c60) electron transport laag (ETL), een tinoxide (Snox) bufferlaag, een andere ITO-laag, een spiro-ttb htl, een verdampte cspbi2br perovskietlaag met een energiebandgap van 1,88 eV, C60 als ETL, een andere Snox-buffer, ITO, zilver (Ag) en magnesiumfluoride (mgfx).

Physical vapor deposits (PVD) was used for the perovskiet -absorber, loading transport layers and indium tinoxide (ITO). The deposit of the atomic layer was used for the Snox layers.

‘By keeping the substrate at room temperature throughout the entire process, we showed a path to fully evaporated, solvent-free manufacture of multi-junction devices. This approach also corresponds well to industrial requirements and opens new possibilities for the production of solar energy with a high transit, “said Gupta.

The test results of the Triple-Junction device champion showed a power conversion efficiency of 21% under environmental conditions without encapsulation, and an open circuit voltage of 2.83 V over an active area of 1 cm2. The PCE improved to ~ 22% after 110 hours of fixed voltage processing under environmental conditions without encapsulation.

The details of the cell were presented in “Photo-based inorganic perovskiet-absorber via thermal evaporation for monolithic perovskiet/perovskiet/silicon triple junction solar cells“Published in Progress in photovoltaic.

The research group has plans to further optimize the evaporation to improve film crystallinity and to coordinate the inorganic perovskiet band gap for better current matching in multi-junction cells, and to make fully evaporated perovskiet cells for integration in perovskite-ski-junction machines.

This content is protected by copyright and may not be reused. If you want to work with us and reuse part of our content, please contact: editors@pv-magazine.com.