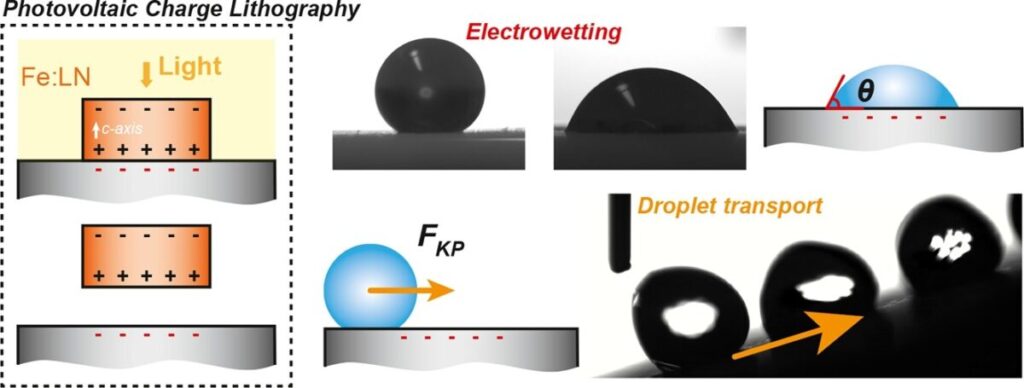

Scientists have used photovoltaic cargo lithography to shine surface drawers on passive dielectric substrates by shining an iron -doped lithium niobate on a halogen lamp. The technology can support microflïdic, biomedical and chemical applications of the next generation.

Researchers from the German University of Münster and the autonomous University of Madrid of Spain have developed a method for Druppelmanipulation using photovoltaic load of lithography. The technology uses the photovoltaic effect of iron -doped lithium niobate (FE: LN) to press surface costs on various passive dielectric substrates, including flexible and disposable polymers.

“The Possibility of Printing Surfaces Charges With An Optical Method on a Wide Variety or Dielectric Materials is particularly interesting for microfluidic and lab-on-a-chip, Including Biomedical and Chemical Applications, Since’s manipational samples) by electric field, Without the introduction of Exensive and Cumbersome Electrodes on Disposable platforms, ”Researcher Riccardo Zamboni told PV -Magazine. “It offers a scalable, re -configurable platform for the next generation of microfluïdic, biomedical and chemical applications.”

The researchers have loaded various passive dielectric substrates (PDSS), including polymethyl methacrylate (PMMA), polyethylene -terefhtalate (PET), polydimethylsiloxan (PDMS), polytetrafluorethylene (ptfe) play. They placed a monster of iron -doped lithium niobate (Fe: LN) on each substrate and exposed it to a halogen lamp. After the photovoltaic lith -lithography process, the PDS surfaces kept costs that researchers followed in Druppel experiments.

“In the case of humidification experiments, the contact corner of a five μl Milli-Q water drop is compared between those with non-fertilized PDs and that on loaded PDs. The contact corner of the drops is checked by a CMOS camera linked to a magnification system,” the researchers explained. “In the drop transposition experiments, a three UL drop is released on the charged PDs in a shifted position in relation to the charged pattern. The drop dynamics during transpor experiments are recorded with a fast camera.”

Zamboni said that several important findings from these experiments emerged.

“Droplets were successfully transported a slope of 17 °, achieving gears up to 1,628 ± 60 mm/s², purely because of the printed charging patterns – without external electrodes or moving parts,” he said. “The method reached a maximum contact corner variation of 81 ± 12 °, which converts hydrophobic surfaces locally hydrophilic, making electrowing on demand possible.”

Zamboni claimed that the technology is one of the first to use only light to print cargo patterns for drop manipulation, which offers strong spatial control and flexibility.

“A single printed charging pattern could put on and merge several drops in order, which demonstrates both reusability and precision,” he said. “Moreover, experimental results closely correspond to numerical simulations based on the Kelvin polarization power.”

The researchers said they intend to continue to develop photovoltaic lithography.

“We are developing a holographic approach to structure the light pattern, making random 2D load distributions with a high spatial resolution possible. to broaden optics. “

They introduced the new method “Photovoltaic load of lithography for drop transport and electrowing on passive dielectric substrates,Which was recently published in The Journal of Colloid and Interface Science.

This content is protected by copyright and may not be reused. If you want to work with us and reuse part of our content, please contact: editors@pv-magazine.com.