New research from China shows that ultra-narrow interconnections can significantly improve organic PV performance. The scientists built a panel of 11.08 cm2 with an impressive geometric fill factor of 98%.

A Chinese research team has fabricated ultra-narrow junctions for organic solar modules using 355 nm ultraviolet nanosecond laser processing. The researchers claim to have achieved a connection width of 80 μm, which until now was only possible with femtosecond pulse lasers.

“The higher cost and increased energy consumption of femtosecond pulse lasers can pose potential challenges, especially within large-scale manufacturing processes,” they said. “This study presents a cost-effective and reproducible approach for the production of high-performance organic solar cell modules (OSC).

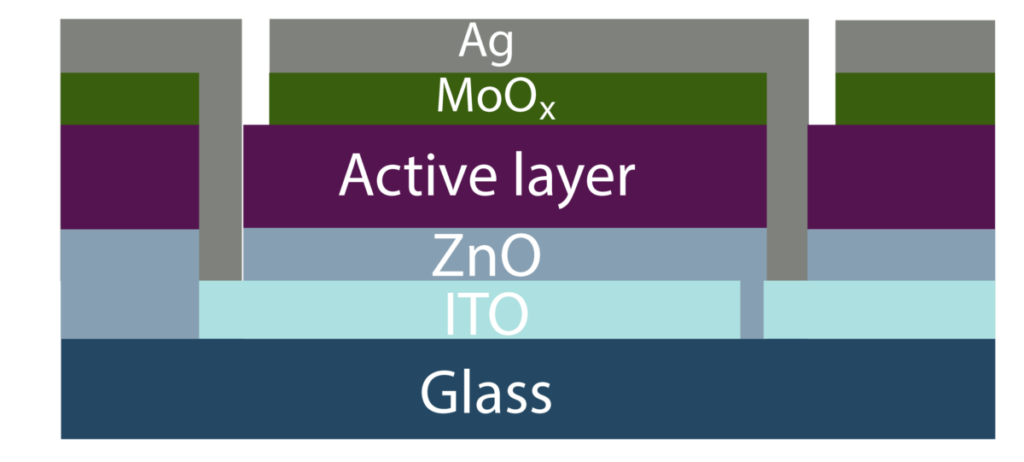

As a representative case, they chose an OSC system with a thin film layer of indium tin oxide (ITO), with zinc oxide (ZnO) as the electron transport layer. The active layer was made of the heterojunction polymer material PM6:L8-BO: PC61BM, a molybdenum oxide (MoOx) layer and a silver (Ag) metal contact. The substrate was based on glass.

“The main obstacle hindering the commercialization of OSCs lies in the challenge of scaling up laboratory-scale cells into large-area modules,” the research group explains. “One of the challenges is preparing to effectively connect cells into modules while minimizing efficiency losses. If the large-area devices are configured as one large cell instead of connected in series, the limited conductivity of the transparent electrodes, such as ITO, leads to losses in series resistance, which in turn causes efficiency losses.”

To solve this problem, a laser scratch approach is often used to create an integrated series connection using the P1-P2-P3 patterns. In their study, this writing was done with the cheaper laser processing in nanoseconds.

In the P1 stage, the ITO thin film is cut into strips that define the subcells. The Q pulse width is optimized at a constant of 4.0 μs. After research, the scientists discovered that spikes created during this process do not reduce the performance of OSC modules.

The next write step, the P2, “is designed to remove any layers stacked on top of the ITO layer, leaving the ITO intact and thus creating good ohmic contact between the ITO cathode and the Ag anode.”

The scientists found that this can be achieved with a Q-switched pulse width of 4.5 to 6.6 μs, as they all showed similar results. “Increasing the Q-switched pulse width to 7.7 μs does not result in complete removal of the active layer. As a result, this leads to a decrease in all module device parameters,” she added. “These results clearly confirm that the P2 process window can be significantly wider after a precise balance between the subcell width and marking depth of laser etching.”

The goal of the final step, the P3, is to segment the Ag film into individual strips to define the subcells. To do this, the academics applied two methods – shallow inscriptions (P3-S) and deep inscriptions (P3-D) – and found that the OSC showed similar performance in both cases, P3-S and P3-D.

“After optimizing the laser parameters for the P1, P2 and P3 writers, a narrow pattern area is obtained. The width of the junction is reduced to approximately 80 μm, which is the narrowest width when using a nanosecond laser and is comparable to a femtosecond laser,” they said. “The subcell width is strategically set at 4.1mm to maximize module area and achieve an impressive geometric fill factor of 98%, achieving the benchmark for nanosecond laser-fabricated OSC modules.”

The module fabricated a device with an area of 1 cm2 and delivered an energy conversion efficiency of 17.55%. “An efficiency of 16.10% was achieved for an OSC module with an active area of 11.08 cm2, which is the highest efficiency reported to date for organic solar panels,” the group added. “Impressively, the best performing OSC module achieved a remarkable geometric fill factor of 98%, leading to a certified efficiency of 15.43% over an opening area of 11.30 cm2.”

The new approach was presented in “An organic solar panel with 16.10% efficiency and ultra-narrow interconnections, fabricated via nanosecond ultraviolet laser processing”, published in Cell reports natural sciences. The group included scientists from China’s Central South University, Chinese Academy of Sciences, City University of Hong Kong and China’s National Center for Nanoscience and Technology.

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.