Developed by researchers in China, the TOPCon solar cell was screen printed with a silver and aluminum paste on the front and an aluminum-only paste on the back. They added silicon to the aluminum paste to reduce metal recombination and improve the open-circuit voltage of the device.

Researchers from Yangzhou University in China have fabricated a solar cell based on tunnel oxide passivated contact (TOPCon) technology by reducing the use of expensive silver paste with a screen-printed aluminum (Al) paste.

“We are still adjusting further processes and Al paste to improve efficiency,” says the corresponding author of the study, Jianning Ding, narrated pv magazine. “We are testing this innovation together with the Chinese solar panel manufacturer JA Solar and paste manufacturer Ruxing Technology Development Co. Ltd.”

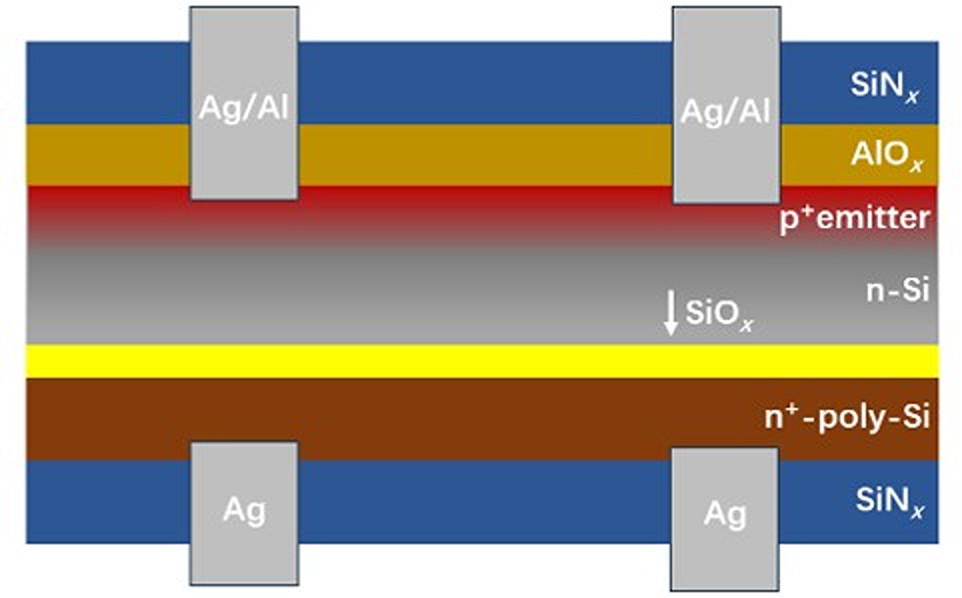

The group built the 182 mm x 182 mm cell on a 140 μm n-type Czochralski wafer. The passivation contact structure on the back side was based on a 1.6 nm silicon monoxide (SiOx) layer and a phosphorus-doped polycrystalline silicon (250 nm) layer, both of which were formed by low-pressure chemical vapor deposition (LPCVD). The device also features an aluminum oxide (AlOx) layer fabricated by atomic layer deposition (ALD).

The cell was then screen printed with a mixed paste made of silver (Ag) and Al on the front and a full Al paste on the back. “The addition of silicon to Al paste can affect the vigorous reaction between Al paste and n+-poly-Si, but can also reduce the conductivity of the lattice,” the researchers specified. “For example, the Al paste with different weight percentages of silicon was used for metallization.”

“Adding silicon to aluminum paste can suppress the reaction between the aluminum paste and poly-Si, thereby reducing metal recombination and improving open-circuit voltage,” added study co-author Qinqin Wang, noting that ohmic contact was established with the formation of Al-Si alloy. “The thickness of the Al-Si alloy decreased as the weight percent of silicon in Al paste increased.”

The scientists explained that the solar cell sample built with the highest percentage of silicon achieved the best performance. Tested under standard lighting conditions, this device achieved an energy conversion efficiency of 22.56%, an open-circuit voltage of 663.6 mV, a short-circuit current density of 40.73 mA/cm2 and a fill factor of 83.48%.

“Although the efficiency was 9.40% relatively lower than that of TOPCon cells printed with Ag paste, the cost of Al paste was only 10% of Ag paste;” they explained further. “In the future, the highest efficiency of TOPCon solar cells printed with Al paste on the back is expected to reach the commercial TOPCon based on Ag paste, which uses laser doping, selective emitter technology (SE) and bifacial poly -Si passivation structure. ”

This content is copyrighted and may not be reused. If you would like to collaborate with us and reuse some of our content, please contact: editors@pv-magazine.com.