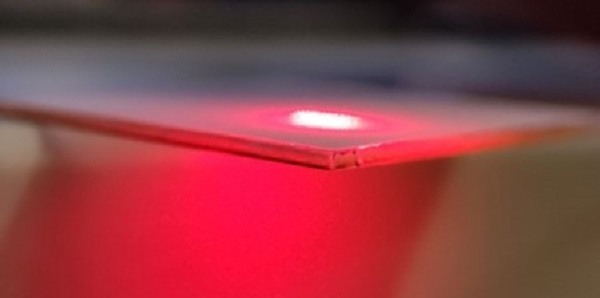

Researchers from Aalto University in Finland showed a proof-of-concept of laser-processed glass that should be used as a type of solar concentrator for building integrated PV (BIPV) applications. The treated glass made a 55-fold increase in the photo flow generation possible compared to unprocessed glass, with an estimated optical efficiency of 0.66 %. In addition, a fluoropolymer coating was applied to create a self -cleaning surface.

The Finnish researchers of the Aalto University investigated with the help of a one-step femtosecond laser directly writing process to produce a proof-of-concept based on nanog-structured commercially available borosilicate glass for buildings-integrated photovoltaics (BIPV).

It is seen as an alternative to conventional luminescent solar concentrators (LSC). In the past, LSC technology has been proposed to improve the efficiency of PV panel or to improve plant growth in greenhouses, and in other industries such as photonic devices in photo microractors for fine chemical production.

“The most important novelty of our research lies in applying a nanopaturtern to window glass using a very simple, cost -effective laser process with one step,” said Xiaolong Liu, accompanying author PV Magazine, If you point out that, in contrast to LSC devices, which depend on the depositing of luminescent materials on glass, the method immediately changes the glass surface itself.

“This pattern changes the way in which light reproduces through the glass, while in a conventional window almost all light continues, and in an LSC light is absorbed and re-sent by luminous materials, our pattern surface enables us to adjust the light path, to propagate up to 10% of it along the glass,” he also said.

“This regulated detour opens exciting possibilities for buildings-integrated photovoltaisi (BIPV), where the guided light on the window frame can be harvested. Moreover, the simplicity of the manufacturing process offers potential for greater design flexibility for complex aesthetical patterns,” added Liu. “Our next steps are aimed at improving the optical efficiency of the nanostructured glass, which is still relatively low at 0.66% and needs further improvement.”

The calculated optical efficiency was indeed estimated at 0.66 % for the sample of 400 mm/s, which the researchers contrasted with LSC designs in the literature that achieved an optical power efficiency of 7.8 %.

The details of the research work appear in “Femtosecond-Laser surface nanostructured glass for building-integrated photovoltaic‘Published by Materials and design.

The team used commercially available glass waffles with a thickness of 0.7 mm as the substrate. The lasert texture was a maskless trial in ambient air with the help of a ready-made femtosecond laser, which worked on a 520 Nm working range, which resulted in a pulse duration of 324 fs, a repeat speed of 417 kHz and an estimated spotdiameter of 10 µm on the Brandpunt.

The laser spot was aimed at lenses with a focal length of 100 mm and a working range of 515-540 Nm. The samples were line by line with line with linear polarization direction aligned with the scan direction. The line scan had a distance of 10 µm exclusion with the spot diameter to ensure that the entire surface was formed by the laser.

“The Fluence was kept constant at 34.4 y/cm2 and the scanning speed was adjusted within a range of 200 – 2000 mm/s,” the team said.

In the research of the results it said that the nanostructured glass, in particular when it is processed at an optimal speed of 400 mm/s, improved the “considerable” wave guidance and the overall optical efficiency of the concentrator system.

A photo flow rise up to 55-time compared to unprocessed glass was measured. “We attribute this to the balance between the total scattering capacity and the transmission; lower scanning speeds produce more nanoparticles that spread lightly, but also slight transmission in braking,” the researchers said.

The characterization of the effect was a challenge, according to Liu who said that measuring how much light was spread to the edges in a reliable way, was “not trivial” because conventional optical measurements were typically designed for transmission and reflection instead of lateral light. “The development of an effective test setup to quantify this effect became an important part of the project, which added an extra discovery layer to the process,” said Liu. The characterization was based on scanning electron microscopy, X-ray relief, Raman spectroscopy, photoolumin-lectroscopy and spectrophotometry.

In addition, the researchers used a fluoropolymer coating to offer a superhydrophobic surface to provide self -cleaning properties. “The superhydrophobic properties, with promoting and withdrawing contact angles of approximately 170 °, achieved after the treatment, makes the self -cleaning function of the nanostructured glass possible,” the researchers said.

“With the help of femtosecond laser directly writing, a simple, robust and scalable method, we successfully create complicated nanopartjesagglomerates on borosilicate glass, which are crucial for effective light spreading, especially within the UV-visible reach,” concluded the team that the team has concluded that the team has that the team Groot area performance.

There are also plans to investigate the design of Nanopaturtern through simulations and optimization of manufacturing process, and combining a nanostructured surface with luminescent materials to further improve efficiency.

Image: Aalto University, Materials & Design, Creative Commons License 4.0

This content is protected by copyright and may not be reused. If you want to work with us and reuse part of our content, please contact: editors@pv-magazine.com.

Popular content