Scientists in Turkey have conceived new solar module electrically conductive adhesives based on silver microflakes and optimized polymere additives. The proposed adhesives were found to increase the electrical conductivity, the attachment strength and reliability under Real-World operating conditions.

Researchers from the Middle East Technical University (Metu) in Turkey have developed on water-based electric conductive adhesives (ECAS) that have been specially designed for geared perc type solar cells.

Shingled panels have a bus-free structure in which only a small part of the cells is not exposed to sunlight. The cells are connected to electrically conductive glue to form a belts with high density and the resulting strips are connected. The reduced number of buses reduces the shadow losses.

“In contrast to conventional solvent -based adhesives that broadcast volatile organic compounds (VOS), the newly formulated glue is entirely water -based and offers a green and safe alternative to photovoltaic production,” the main author of the research, Husnu Emrah Unalantold PV -Magazine. “By using silver micro-flakes, biodegradable additives and optimized surfactive substances, the formulation reached the volume resistance of 22 uΩ/cm for a film thickness of 25 μm, a glue yield voltage of 4.8 mpa, and a 0.4% absolute absolute-congregate in comparison with an absolute-seven-version of the absolute-version-version-version-version-version-version-converting Commercial reference ADHESIVE. “

In the newspaper “Water-based electrically conductive glue for perc-type Shingled Solar cells“Published in Solar energy materials and solar cellsThe research team described the new ECA as a water-based system with AG-Micro-Flakes as the conductive filler, where the primary components are a non-specified environmentally friendly binder system, dispensers and reologue modifications.

The binder was chosen because of its organic, water -soluble, biodegradable and environmentally friendly properties, the academics said, without providing further details.

“The specific formulation of the electrically conductive ink used in this study is currently the subject of a hanging patent application, and detailed composition information cannot be announced at the moment,” they added. “All other materials and processing parameters are described in the extent necessary to guarantee the reproducibility of the methods used in this study, while business details remain protected.”

The scientists validated the performance of the ECA through full outside tests on the Metu-Günam photovoltaic module Outdoor Test Field in Ankara, Turkey, with Real-World tests that confirm the long-term and mechanical reliability over time.

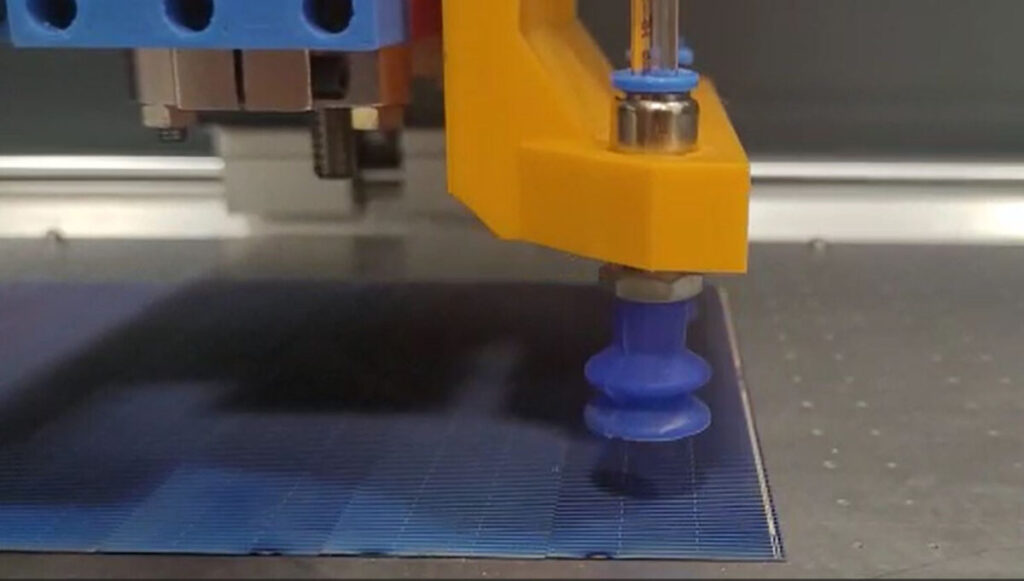

They brought the ECAs via Direct Ink Writing (DIW) with a 27-Gauge mouth piece with an inner diameter of 0.21 mm to perform deposit and control glue distribution. For two interconnected comics they used 0.1 g ECA, while for a full set of 15 pairs of strips the total ECA consumption was 16 g.

The validation process showed that the ECA offered homogeneity, high gaskeeping density and the desired reological properties for PV applications. It was also found to provide high strength adhesion without porosity and agglomeration in the microstructure, the researchers said it is the key to achieving good performance in solar cells.

“This development is an important step in the direction of sustainable solar panel assembly and promises promise for integration into flexible electronics, portable devices and green electronic production lines. Commercialization processes of the conductive glue take place at Spin-OFF company, Nanovatif material technologies,” ” Emrah Unalan Closed.

This content is protected by copyright and may not be reused. If you want to work with us and reuse part of our content, please contact: editors@pv-magazine.com.

Popular content