If lithium-ion battery fires are virtually impossible to prevent, containing thermal eliminated events is crucial. Battery Energy Storage System (Bess) supplier Viridi Recently, a live fire -demonstration organized to show how well -designed cell modules of fire forecast can prevent.

“The real problem is not the thermal -running event,” said Jon Williams of Viridi PV Magazine USA. “It is the spread of a fire from one cell to the other. There you get catastrophe.”

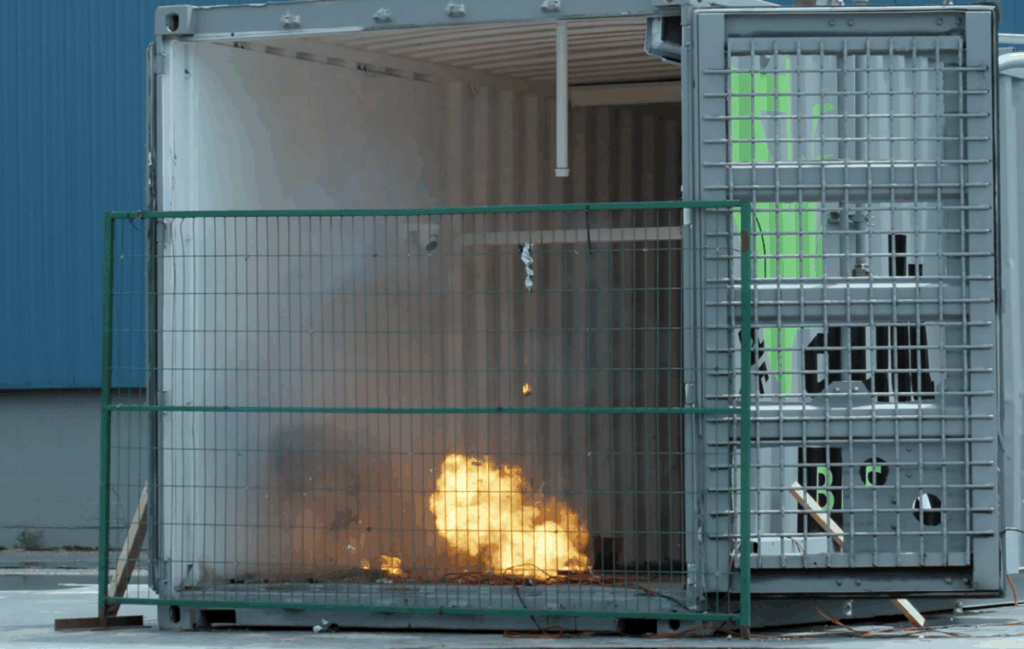

During the live demonstration part of the battery safety event of Viridi, held on 15 May in the 43 -hectare technology center in Buffalo, New York, in collaboration with the Soteria Battery Innovation GroupTechnicians initiative with a thermally eliminated event in a standard battery, resulting in cell-to-cell propagation. The test of a second package equipped with the thermal insulation of Viridi and the anti-propagation barriers limited the fire to the activated cell without affecting the others.

“When you set up a 50 kWh package and your witness to the energy and smoke and gas that comes out of that package, you have enormous respect for that technology,” Williams said. “The good news is that it is really energy. On the other hand, it is really energy -tight.”

Although there are many strategies to reduce the risk of thermal events, from the selection of battery chemistry to managing the operational environment, the fact is that when you have a large installed basis in the field, something will happen.

Williams said that JR Linna, the head of the development and development of Viridi, told him that there is a chance of failure for one of one in so many millions of cells, regardless of who makes them. Because at some point you can get a short that creates enough heat and sends the cell in a catastrophic failure, regardless of how many sensors you put on it.

Ultimately, Williams, is an event beyond all the safety. He wondered how that can be stopped, but Linna said it really can’t be stopped.

For this reason, Williams said that the approach of his company is to start with effective chemistry and then develop the strongest package for inclusion. Viridi originated in 2018 and made battery packages for the construction sector, where Williams says that equipment is being handled roughly routinely. The company produces a battery container made of quarter-inch, grade 50 steel as the first line of defense against thermal events. The goal was to get physical damage from the comparison.

“In the compact hardware store, equipment is beaten pretty poorly,” he said. “They lift things on buildings, they put it on the back of trucks, they drop it from things, it falls into ditches, it goes in ponds. Compact construction equipment is really only chic hammers; they beat them to death.”

In addition to reducing the risk of physical damage to the bess unit that can cause a fire, the inclusion system is designed to prevent the reproduction of a fire in one cell that influences adjacent cells. As calculated above, a battery will in one way or another fail that a thermal event is produced. Because it is not always possible to predict where the failure will occur, every cell package must be as strong as possible.

Williams explained that the Bess modules of Viridi were designed to contain the three aspects of a thermal eliminated event: the enormous heat (more than 700 degrees Celsius); Explode particles; And a concussion wave. Chanryized steam produced on liquid -based cooling bodies that prevents adjacent cells from rising more than 170 degrees Celsius, Williams said. Spacers between the cells disappear the concussion to prevent it from compressing the side walls of adjacent cells.

Fire safety of lithium-ion batteries is a growing problem for an ever-increasing series of stakeholders who go beyond manufacturers and users, including people who live under vehicle batteries and currant installations. As a result, First -Responders, supervisors and codes and standards organizations have difficulty catching up with the right rules and techniques.

Earlier this month, Bess Provider Sungrow announced that the liquid-cooled Powertitan 2.0 system had received approval from the New York City fire brigade that clears the way for the use of his lithium ion system in the city. Last year, Sungrow had hosted His own fire test to demonstrate the thermal management options of the Powertitan.

In that test, which was carried out a test facility in China and streamed live for stakeholders, explosion aid jugs on top of the unit in which the fire was set, the fire automatically raised to prevent it from spreading to adjacent battery units. The test event unfolded without intervention due to personnel or fire suppressing systems until the fire burned out.

According to Mandy Zhang, Sungrow’s battery storage product manager for overseas regions, the increasing installation of lithium-ion batteries on many fields makes a brand incident very announced. This leads to a perception of increased fire risk.

“We believe that the focus of industry on fire risk is mainly due to a lack of understanding of a fire in energy storage systems,” Zhang said PV Magazine USA. “Statistical data show that the actual fire risk is relatively low. Reports from organizations such as the National Fire Protection Association and the US Consumer Product Safety Commission support this.”

Zhang believes that the current fire safety certifications and standards in certain regions are left behind with the rapidly increasing installed base of lithium -ion battery storage. She said battery manufacturers should work with relevant standards agencies to keep them informed of battery storage and management systems.

John Zahurancik, President Americas at battery maker Fluence Energy, Does it agree that expertise Must flow easily between supplies, contractors, operators and first responders to prevent thermal events from making the news and the public perceptions of the safety of lithium-ionbatteries warp.

“If things are not going well, we have to talk about that in the spirit of, hey, everyone should not learn this lesson alone,” Zahurancik told PV Magazine USA. ‘We are part of the American Clean Power Association And one of the big pushes is to collect part of this information and to spread the best safety approach. “

The industry responds with more intensive test and evaluation methods for Bess. In March Ul Solutions revealed The new UL 9540A methodology to determine the sensitivity of a battery technology for thermal runner.

Nevertheless, Williams from Viridi said that the Bess industry and his regulators are still getting a grip on managing thermal events and how to manage Bess wider.

“All tests that are happening now are observational tests,” he said. “So you can pass 9540 and still have an explosion later because of something unseen. We need a conversation there.

This content is protected by copyright and may not be reused. If you want to work with us and reuse part of our content, please contact: editors@pv-magazine.com.

Popular content